About the IDC

The EngD in Composites Manufacture is a four-year postgraduate research programme, for researchers who aspire to key leadership positions in industry.

A Centre for Doctoral Training

- Integral activity of the Future Composites Manufacturing Research Hub and a collaboration between the Universities of Bristol (lead university), Cranfield, Manchester and Nottingham

Developing elite Research Engineers

- Addressing the urgent and growing need across the UK polymer composites manufacturing sector for engineers ready to take on key leadership positions in industry

- Equipping Research Engineers with the necessary advanced technical and leadership skills required for effective adoption of new knowledge and technologies in composites manufacture

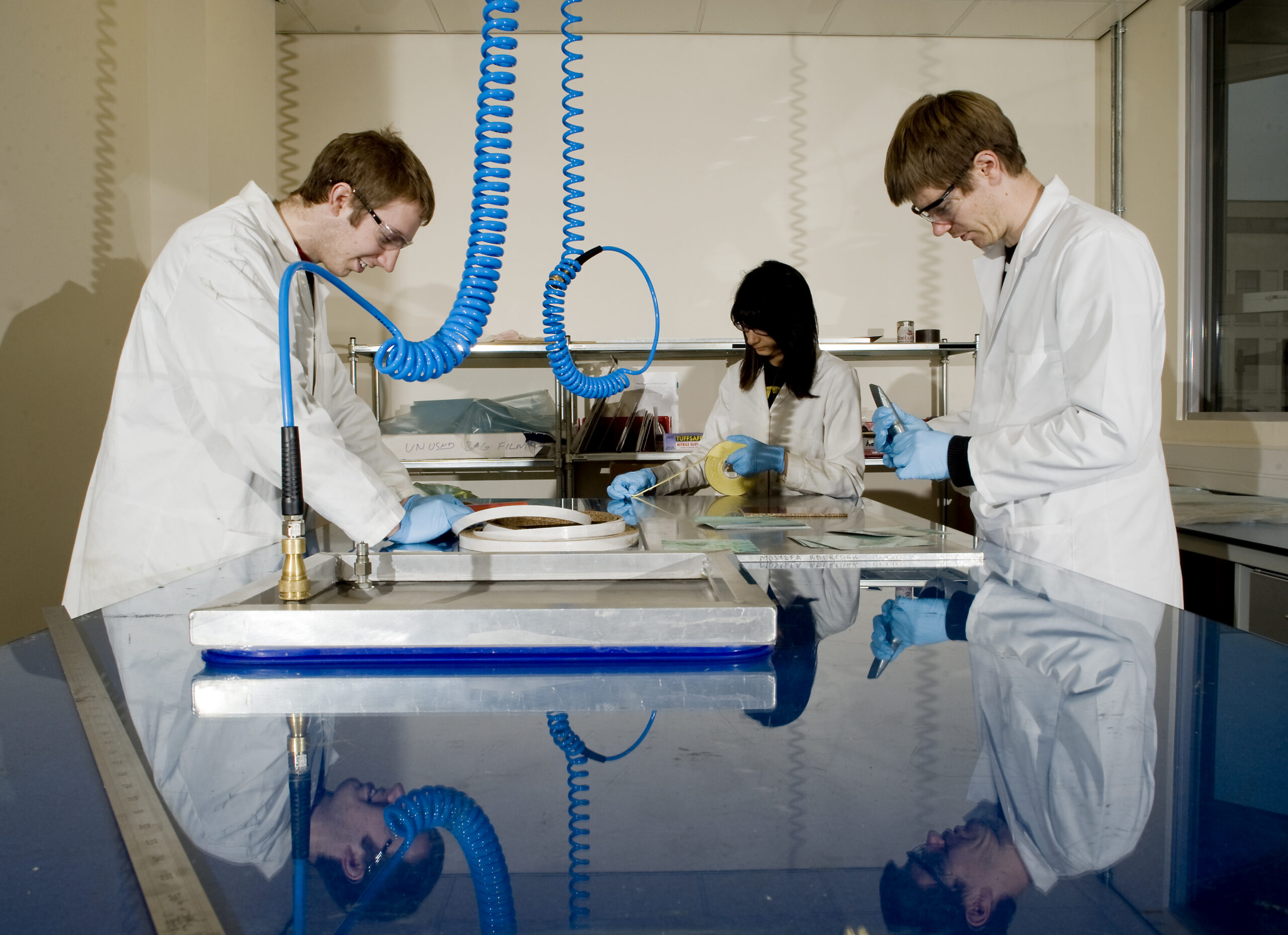

Industrially-focused research

- Research projects are industry-based and industry-led and aim to address the sponsors commercial research priorities

- A programme of bespoke Masters-level technical units and business skills training ensures Research Engineers bring considerable specialist knowledge and capability to their project

- Theme area: manufacturing of engineered composite structures

- Relevant industry sectors: aerospace, automotive, marine, wind energy and construction

- Applied research activity focussed on TRL: 3-5

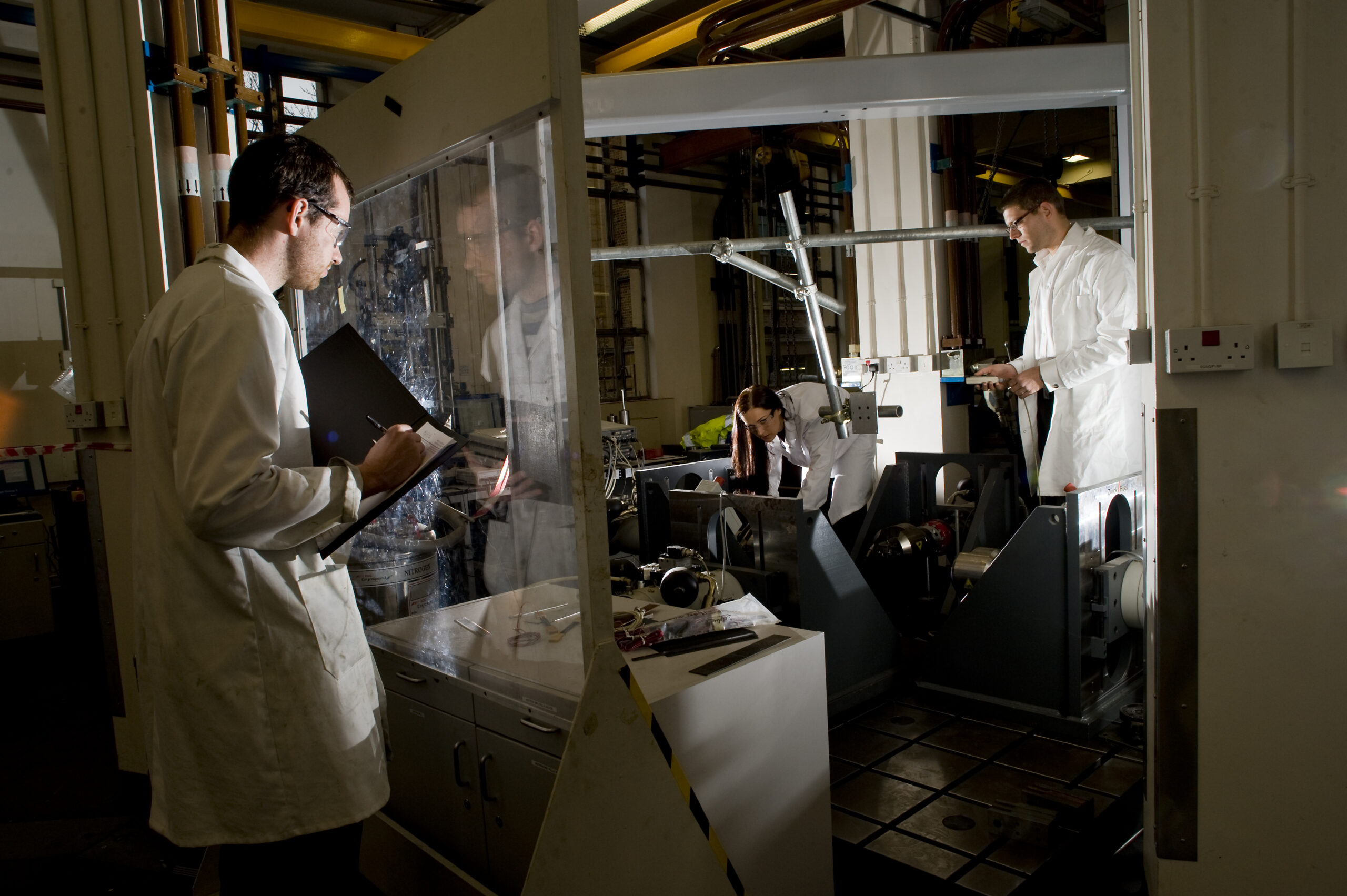

Academic excellence and access to resources

- Constant flow of cutting-edge ideas between the sponsor company and leading academics within the relevant field

- Access to a complete range of equipment and techniques at the UK National Composites Centre (NCC)

IDC Alumni Ashley Barnes

“The IDC was a great experience that integrated me into a network of world class engineers. Being part of this network provided immense support and insight that was rewarding, and strengthened my output. The confidence gained during my time in the IDC has helped me to accelerate my career into technical authority and deliver results in subsequent roles for varied companies. I currently work as a Design Manager for Babcock International.”

“The Engineering Doctorate (EngD) in Composites Manufacture sponsored by the National Composites Centre gave me the perfect environment to develop the skills, competencies and network I needed to fast track my career in the composites industry. The mix of experiences and opportunities I had through this program was absolutely unique. In the same four years, I developed the academic skills needed to conduct and deliver research at doctoral level, delivered consulting R&D work to global companies in the aerospace industry, gained foundational business and technology management knowledge, and rounded my competencies in many critical areas such as leadership, influence, and communication. I truly believe that I would not be where I am today if I hadn’t taken the opportunity to join the EngD. ”

IDC Alumni Dr Mattia Di Francesco, Business Development Manager at Airborne