Incremental sheet forming of fibre reinforced thermoplastic composites

Host Institutions: The University of Bristol, The University of Nottingham

Start Date: 1st April, 2020

Duration: 6 months

Lead Investigator: Mike Johnson

Co-Investigators: Hengan Ou, Mike Elkington, Preetum Mistry

Executive Summary

This feasibility project, Incremental Sheet Forming of Fibre Reinforced Thermoplastic Composites, aimed to form fibre reinforced thermoplastic (FRTP) sheet material using the diaphragm forming (DF) process enhanced by the robotic, incremental sheet forming (ISF) process. This method is termed the Hybrid Vacuum Robotic, or HyVR, forming process.

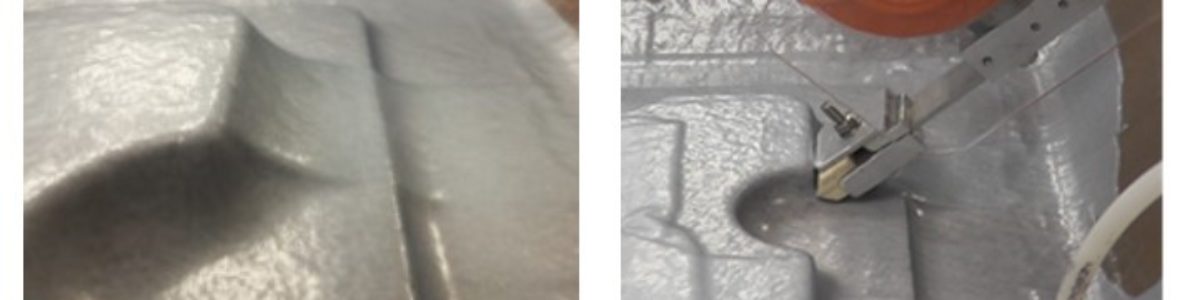

The traditional DF process allows shaping of pliable sheet material over a mould at forces limited by vacuum pressure. Pliability of FRTP occurs above the melt temperature. The low vacuum forming forces enables low cost, rapid prototyped moulds to be used. Scaling to large part sizes is possible with no penalty as the forming forces remain limited to vacuum levels. Two main defects arise using DF: ‘bridging’ and ‘wrinkling’. FRTP bridging occurs at tight internal radii. Wrinkling of the reinforcement can develop when forming complex geometry. Strategically applying a supplemental normal force and a tangential smoothing force using a shaped end effector can overcome bridging and wrinkling defects, respectively. In the HyVR process, the path of the end effector is controlled by a computer numerical control (CNC) 6 axis robot. The over-arching aim is to manufacture large FRTP components in medium volumes (approximately 4-6 pph) and at low cost using the HyVR process.

In the feasibility study a lab scale HyVR cell was implemented. The forming strategy which drives the HyVR process through sequencing of the DF and ISF techniques was developed. In addition, experimental methods were defined to quantify the FRTP material characteristics (cone study) and associated thermal forming window. These are direct inputs to the HyVR forming strategy. Cone forming FRTP was not possible due to edge clamping of the inextensible reinforcement. Techniques to extend the forming window time still are required. Using the HyVR process, forming strategies were determined to produce single curvature parts without bridging. The quality of these components was equivalent to benchmark components made by hand layup. Forming strategies for double curvature components requiring in-plane fabric shearing were produced. While successful, further improvements to the forming strategy are required to minimise wrinkling in double curvature components.

This feasibility study aligns with the overall aim of the EPRSRC Future Composites Manufacturing Research Hub (the Hub) to promote the benefits of thermoplastic composites. Organisationally, the feasibility study forms part of Workstream (WS8): Thermoplastic Processing Technologies, within the research priority area: ‘High-Rate Deposition and Rapid Processing Technologies’. This seeks to meet the Grand Challenges of the Hub to enhance process robustness and develop high-rate processing technologies.

This feasibility study posed the research question, “Can the HyVR process form FRTP sheet material to single and double curvature?” The research conducted as part of this feasibility study demonstrated that this could be achieved.