Incorporation of thermoplastic in situ polymerisation in double diaphragm forming

Host Institutions: The University of Nottingham, University of Edinburgh

Start Date: 1st April, 2020

Duration: 6 months

Lead Investigator: Andrew Parsons

Co-Investigators: Adam Joesbury, Conchur O’Bradaigh, James Murray, Lee Harper

Executive Summary

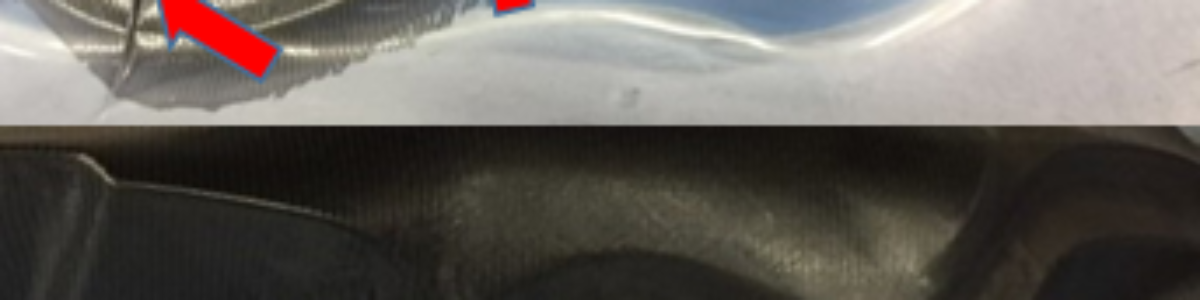

Double diaphragm forming (DDF) is a process for producing complex, large preforms for out of autoclave processes. DDF generally requires lower capital investment compared to matched tool forming, but defects such as fibre bridging and fabric wrinkling are more likely to occur. To improve on this, DDF has been combined with a liquid infusion process, where a dry fabric stack held between two flexible membranes (diaphragms) is infused with resin prior to being formed. There are several benefits for doing this:

(1) The resin infusion step is performed with flat fabric plies, simplifying the filling stage without geometrical constraints.

(2) Forming occurs in the presence of a low viscosity liquid, reducing inter-ply friction and diaphragm-fabric friction, improving fabric conformation to the tool

(3) The infusion and forming stages are combined into one process, saving time and consumables

The project fits within the “high rate deposition and rapid processing technologies” priority area of the Hub and addresses both Grand Challenges. It is also complimentary to a number of existing and prior projects funded by CIMComp, including:

- Acceleration of monomer transfer moulding using microwaves (2018)

- Manufacturing TP fibre metal laminates by the in situ polymerisation route (2018)

- Active control of the RTM process under uncertainty using fast algorithms (2019)

- Modelling forming of multi-ply preforms (2011);

- Multi-scale modelling to predict defect formation during resin infusion (2011);

Overall the project delivered on its objectives, but full realisation of the project was limited by travel restrictions due to Covid.