Work stream 8: Optimised Manufacturing of Structural Composites via Thermoelectric Vario-thermal Tooling (VarioTherm)

Host Institution: University of Warwick

Start Date: 1st March, 2020

Duration: 6 months

Lead Investigator: Ton Peijs

Co-Investigators: Darren Hughes, Neil Reynolds, Teodor Chiciudean

Aims

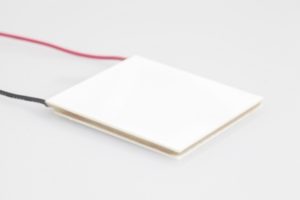

| Heated tooling is of interest for processing of both thermoset as well as thermoplastic composites. Such tooling for thermoplastics typically consist of metallic tooling with integrated heating elements and cooling channels. In the case of thermosets, heated tooling is used for “out-of-autoclave” curing such as resin infusion processes, vacuum bagging of prepregs and SMC compression moulding. Despite the large number of heating technologies commercially available for use in heated tooling, there are still only few systems that allow for local variations in heating and cooling. The current project investigates the use of an array of independently controlled thermoelectric (TE) Peltier modules to enable rapid vario-thermal zone heating/cooling in a metallic mould tool, creating and benchmarking the performance of a single-sided (flat) demonstrator tool for the use of the rapid, optimised processing of candidate thermosetting and thermoplastic structural composite materials.

|

||

|

||