Work stream 8: Rewinding Tape Laying: can Direct End-of-Life Recovery of Continuous Tapes be a Step-Change in the Sustainability of Thermoplastic Composites

Host Institution: The University of Nottingham

Start Date: 1st January, 2022

Duration: 6 months

Lead Investigator: Davide De Focatiis

Co-Investigators: Andrew Parsons, Mike Johnson, Samanta Piano

Aims

Is it feasible to engineer a means of recovering lengths of continuous thermoplastic tapes from end-of-life parts by peeling individual layers under controlled conditions?

The objectives of the six month Feasibility study are to:

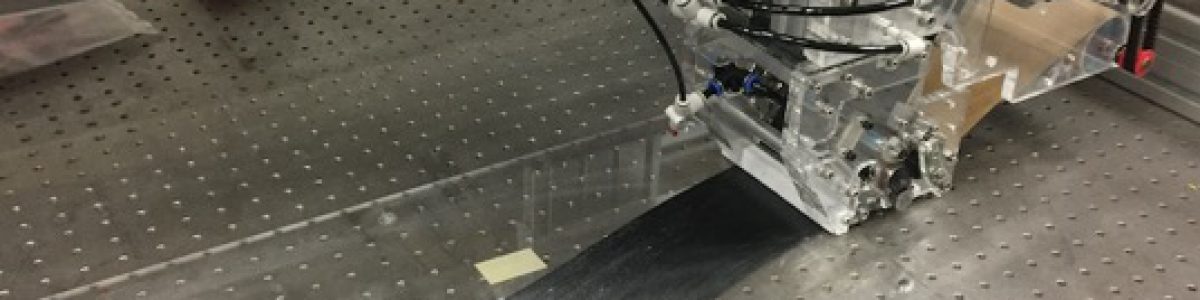

– Instrument a simplified peel tester with controlled heating for thermoplastic tape separation

– Establish the conditions (eg. temperature, force, speed) required to successfully peel a layer of continuous thermoplastic tape from a simple consolidated structure

– Determine the most appropriate metrological technique to assess the viability of recovered material (in terms of waviness, matrix distribution, defects)

– Attempt basic re-processing of peeled pre-pregs and determine composite properties relative to virgin parts

– Provide a framework and initial data for a core project addressing the automated circular manufacturing of thermoplastic composites

This project will explore means of recovering continuous thermoplastic prepreg from end-of-life parts by a controlled thermal peeling process in such a way as to make the peeled plies re-useable in new parts with minimal post-processing.