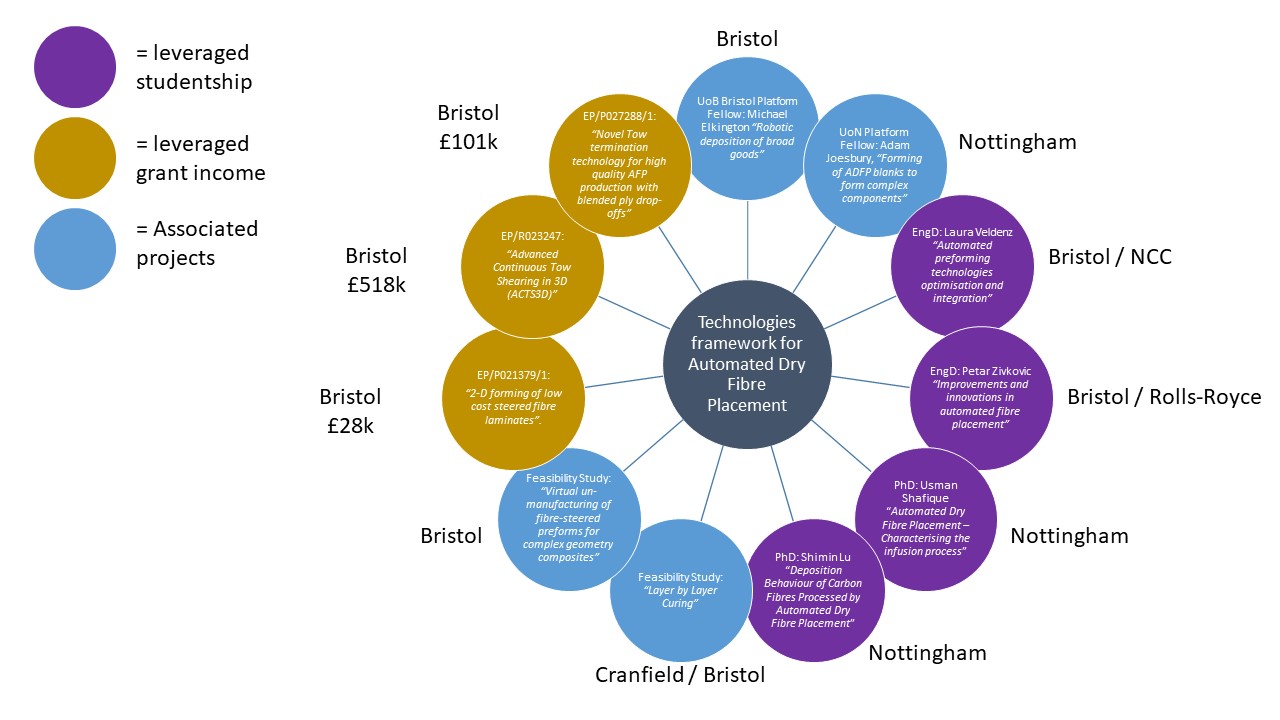

Work stream 1: Technologies Framework For Automated Dry Fibre Placement

Host Institution: The University of Nottingham

Start Date: 1st April, 2017

Duration: 64 months

Lead Investigators: Eric Kim, Thomas Turner

Co-Investigators: Adam Joesbury, Andreas Endruweit, Anthony Evans, David Brigido, Jonathan Belnoue, Ric (Xiaochuan) Sun, Shimin Lu, Stephen Hallett, Usman Shafique

Aims

Automated Fibre Placement (AFP) technology has been adopted within the aerospace industry for the manufacture of carbon fibre reinforced components, such as wing spars, wing box covers and fuselage barrel segments. AFP has the ability to control fibre orientation as a result of its fibre steering capabilities by directing fibres onto a complex geometry or curved surface. The robustness, low wastage and repeatability through automation result in a desirable process for high quality high volume manufacture. AFP eliminates the labour intensive hand layup methodology that significantly increases production times. However, for small and complex parts, the advantages it offers cannot be realised. Furthermore, the current AFP processes can only use continuous fibre tapes, limiting the sustainability of the process. Traditionally, AFP uses thermoset or thermoplastic prepreg slit tapes, using the tack of the matrix material to adhere the fibres into position. However, these materials are expensive, require accurate temperature control during storage and deposition, to ensure sufficient adhesive properties are not effected by aging, and require further consolidation processing, such as by autoclave. The latter further increases initial equipment cost and operation cost as well as cycle times in comparison to liquid composite moulding (LCM) processes. Therefore, automated dry fibre placement (ADFP) has become of particular interest with the aim of reducing cost and cycle times whilst maintaining the high quality and low wastage of fibre placement technologies.

The team at the University of Bristol aim to develop a rapid manufacturing process, using sustainable materials for complex composite parts, which are not manufacturable using current AFP technologies. They will develop and validate a new manufacturing framework to achieve optimal fibre paths to maximise a part’s mechanical performance. Their work consists of four work packages:

- Fast numerical tools that derive the ideal fibre paths of a flat preform from the “as-designed” geometry and fibre orientation of a given part will be developed.

- A sustainable material production method will be used to produce highly-aligned discontinuous fibre (HiPerDiF) tapes suitable for automated process, and the material configuration will be optimised to provide maximum drapability in the forming process.

- Defect-free fibre steering (CTS, Continuous Tow Shearing) process will be modified to feed the HiPerDiF tapes with high stretchability and produce high-quality fibre steered preforms.

- The overall workflow will be demonstrated to show how the technologies developed in WPs 1-3 can be integrated in a coherent, combined workflow to produce a novel, as designed, manufacturable, sustainable “part” at increased rate, with reduced defects.

The team at the University of Nottingham aim to understand the rate and quality limiting effects in the ADFP process and develop models to increase understanding of the critical factors. Their work consists of five work packages:

- Process design to determine hardware effects and control of the deposition apparatus whilst developing lab scale equipment to demonstrate these.

- Material design to investigate the fundamental tow/tape/NCF structure, optimising the binder content (type and volume) for tack and the prevention of fibre fuzzing during deposition.

- Deposition process to quantify the tack properties with respects to rate and temperature of dry fibre systems as well as the studying the compaction and topology to predict behaviour of single tows or ply stacks and their interactions with the deposition roller.

- Infusion process to quantify the permeability effects of the fibre architecture post deposition.

- Part design to part geometric effects in terms of processing rate and quality of the preforms.

Principle investigator, Dr Thomas Turner introducing the University of Nottingham part of the project:

Principle Investigator, Dr Eric Kim introducing the University of Bristol part of the project:

Key Achievements

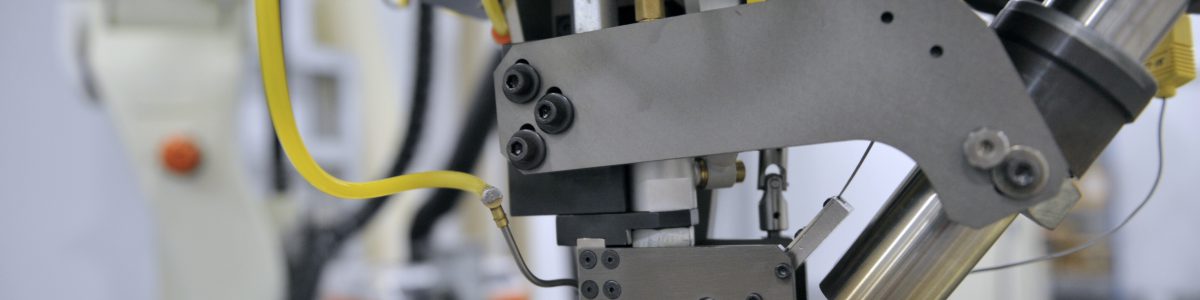

- Manufactured laboratory scale 2D ADFP rig for high rate deposition process (up to 3m/s), with additional sensors to determine fibre position and force/torque.

- SSIdentified a suitable heating method for fast response rates and high heating rates >1000°C/s. Resistance heating trials have been performed to create an initial temperature control, in addition to the creation of a Human-Machine Interface to transfer data between the IPC and server, and synchronisation between the motion and the temperature data.

- Online binder application trials have been conducted using inkjet printing to tailor binder ‘patterns’ for deposition of tow based material to reduce costs.

- The compaction response of stabilised slit tapes has been compared to that of carbon fibre tows.

- Compaction and thermal FEA simulations have been developed to capture the behaviour during the ADFP fibre deposition stage.

- The influence of inter-tow gaps on preform permeability has been studied using numerical models and experimentally measured values using preforms provided by the National Composites Centre. Large scale (>70mm) unit cells have been determined for macroscale infusion simulations implemented within PAM-RTM (ESI Group).