Microwave in line heating to address the challenges of high rate deposition

Host Institutions: The University of Bristol, The University of Sheffield, Wrexham Glyndŵr University

Start Date: 1st April, 2019

Duration: 6 months

Lead Investigator: Richard Day

Executive Summary

The purpose of the study was to explore whether microwave heating could be used during automated fibre placement as a method of increasing the layup rates to the 100 kg/hour requirement, which would enable further use of composites in a range of structures, particularly, but not exclusively aero structures. This fits into two of the Hubs priority areas

1) High rate deposition and rapid processing technologies

2) Design for manufacture via validated simulation

This project is complementary to the core project on the technology framework for automated dry fibre placement and fits within the high rate deposition and rapid processing technologies research priority area in the call.

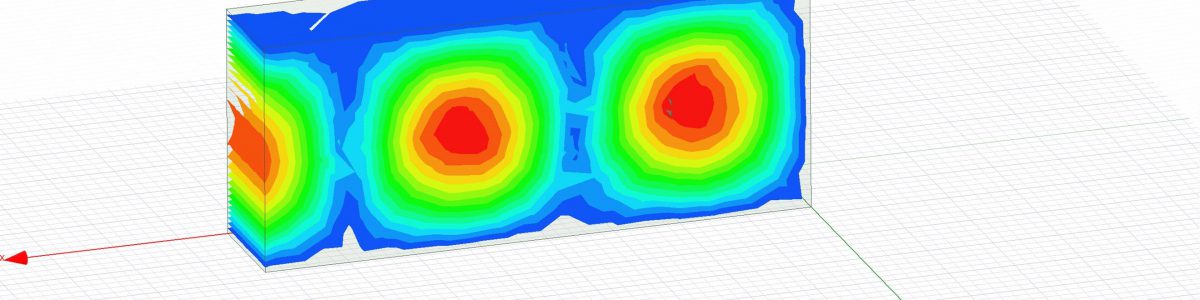

Potential microwave cavities simulated using COMSOL and HFSS software, where two of these were developed in the laboratory. One was, as expected, not suitable due to its size and performance although it was used to trial data for use in validated simulations. The second cavity, a truncated waveguide section, performed well. Simulations of heat up rate in this cavity as well as practical measurements showed that it heated at rates which would be able to hit the target layup rate of 100 kg/hr

The research question was successfully answered. There is mileage in this approach which shows that a practical microwave system of heating during automated layup is possible and desirable. Furthermore it may be possible to combine this with other forms of heating to produce very significant layup rates.