Manufacturing Advances for Smart Through-Thickness Reinforced Composites

Lead Investigator: Stephen Hallett

Co-Investigator: Ivana Partridge

Aims

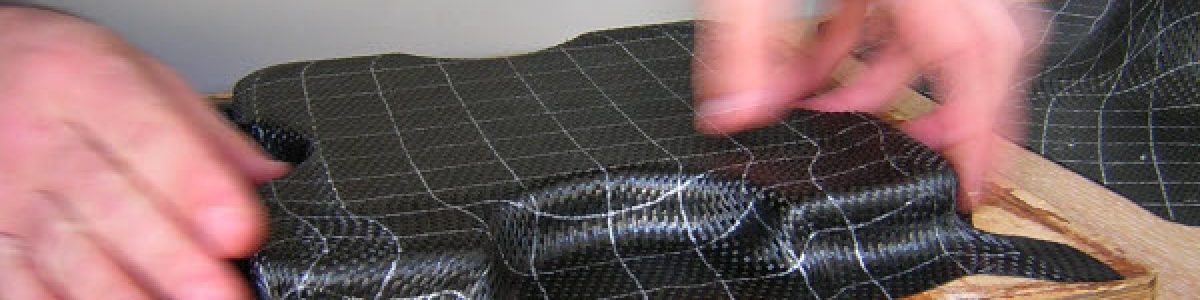

Laminated composites are prone to delaminations due to the presence of interlaminar stress raisers, such as free-edges and ply drop-offs. Through-thickness reinforcement (TTR) inhibits delamination growth by restraining delamination opening and sliding. TTR can be applied in the form of discrete rods (Z-pins), tufts or stitches. Z-pinning [2,6-7] and is particularly effective in enhancing the damage tolerance performance of pre-preg based composites under quasi-static, impact and fatigue loading.

The aim of this proposal is to develop the manufacturing and insertion processes for multi-functional Z-pins for the through-thickness (TT) reinforcement of composite laminates. The main objective is to combine the passive delamination-suppressing action of traditional Z-pins with additional manufacturing-enabled functionalities, namely: 1) delamination sensing and active suppression; 2) active cooling of composite structures; 3) self-healing.

The main assumption underlying this proposal is that the multi-functional attributes listed above can be transferred to an otherwise traditional composite via the insertion of smart Z-pins. Typically a 2% aerial density of Z-pins increases the mode I fracture toughness 40-fold (4-fold for mode II) with respect to the baseline material, with knockdowns on in-plane stiffness and strength below 10% [2, 6-7].

The key manufacturing-related challenges to be resolved are:

- manufacturing Z-pins that have the multifunctional properties

- demonstrating that such Z-pins can be successfully inserted into laminates

- proving that smart functions can be transferred to the Z-pinned laminates