Advanced continuous tow shearing for next generation Automated Fibre Placement (AFP)

Host Institution: The University of Bristol

Researcher: Dr Eric Kim

Aims

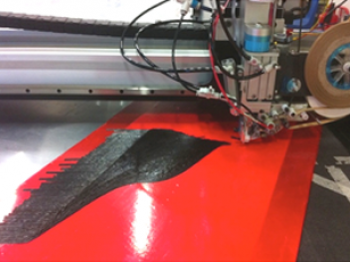

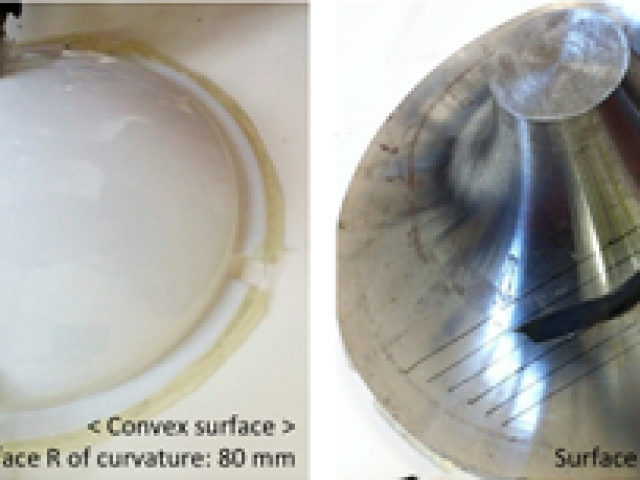

To develop a Continuous Tow Shearing (CTS) process by adding advanced functions for applying the steering capability of CTS to 3D complex geometries. These functions are the conformability of the compaction shoe and the tow width control mechanism. The technical objective is to improve the CTS head with add-on devices for these additional capabilities and to test it in a 2.5D environment as a preliminary stage to complex 3D geometries.

Progress

The developed conformable compaction shoe was tested on the early prototype head which demonstrated its potential for 3D application successfully. The basic concept of the TWiC (tow width control) mechanism was also demonstrated by modifying the in-situ tow impregnation device of the CTS head. The mechanical parts for the TWiC were fabricated and are being assessed independently, which will be trialled on the new CNC platform.

Evidence of Impact

This research is attracting attention from composites researchers at different Universities and industrial partners since the new CTS can reduce complexity of design and manufacturing, and minimise process-induced defects. Close collaborations with structural optimisation groups in Bristol and Bath universities, who are working on variable stiffness structures, were made to enhance understanding of this new technology and exploit new application areas of the CTS.