Cure Kinetics Modelling for Fast Curing of Tough Thermoset Polymer Composites

Lead Investigator: Ambrose Taylor

Aims

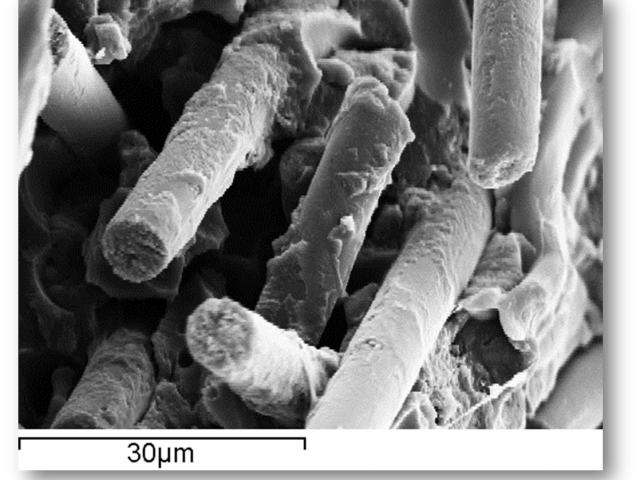

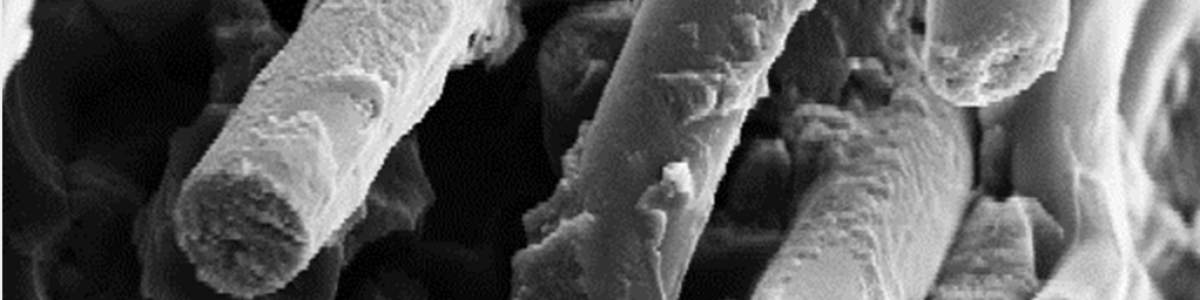

The use of composites in automotive applications for volume manufacturing requires fast, low-cost processing. Such fast processing requires new reactive resin systems, but also requires the modelling of the cure kinetics and rheology to ensure that composite parts can be manufactured successfully. Once developed, such a cure kinetics model can be combined with nanoparticle toughening to allow rapid production of tough fibre composites.The aims of this study were to (a) develop a basic model of the cure kinetics of a silica nanoparticle-modified resin system, (b) combine this model with knowledge of the flow process in compression resin transfer moulding (CRTM) to form a hybrid model, and (c) validate this hybrid model using sample plates manufactured using CRTM.

The cure kinetics and rheology were modelled successfully. Sample composite plates were produced using CRTM. Microscopy showed that the silica nanoparticles were well-dispersed in the epoxy. However, the fast-curing epoxy used was found to not be readily toughened so the fracture energy of the nanoparticle-modified composites was not significantly greater than that of the unmodified epoxy. Additional funding will be sought through grant applications to the EPSRC.