Work stream 6: Compression moulding simulation for SMC and prepreg

Host Institution: University of Warwick

Start Date: 1st January, 2020

Duration: 2 years

Lead Investigator: Connie Qian

Aims

| The project aims to develop a new modelling framework for compression moulding of prepreg and SMC hybrid structures. A range of new material characterisation methods will be developed to understand the essential deformation mechanisms for both prepreg and SMC under typical compression moulding conditions, and new validated material models will be developed, allowing these deformation mechanisms to be captured in process simulation.

The project aims to disseminate the results from the research through conferences and high quality journal publications, and promote the research to higher TRLs through collaboration with industrial partners. |

Progress

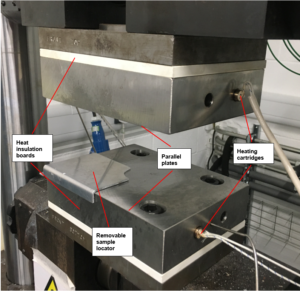

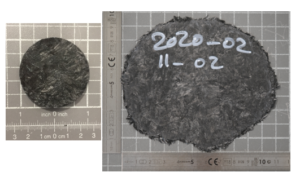

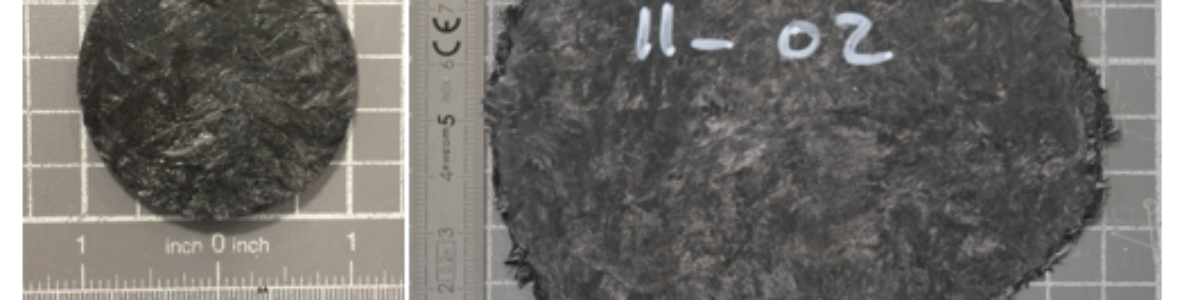

| A squeeze flow testing rig has been designed and manufactured as a part of this project for characterising the flow behaviour of SMC. Prelimenary squeeze flow tests have been performed using a candidate SMC material and the results have been benchmarked against material manufacturer’s data in order to suggest improvement to the existing testing procedure.

Commercial SMC compression moulding simulation software 3D Timon is being assessed to establish the limitations and incorrect assumptions in this process simulation model, providing useful guidance for the new model developed in this project. The PI have led the design of the squeeze flow testing rig, and development of the current testing procedure. The PI have supervised the squeeze flow tests (performed by a project engineer) and analysed all the experimental data. The PI have also organised the 3D Timon training and performed all the process simulation to date. Toray AMCEU have supplied the trial CF-SMC used in this project. And Toray TEK have provided training and a 6-month license for the 3D Timon software and the material card for the trial material. |