University of Bristol Updates on its Activities as Part of the EPSRC Centre of Innovative Manufacturing in Composites (CIMComp)

CIMComp Archive Press Release

Published: 10th September 2013

This forms part of the work undertaken by the EPSRC Centre of Innovative Manufacturing in Composites (CIMComp), led by the University of Nottingham, which aims to deliver a coordinated programme of research at some of the leading universities in composites manufacturing, namely the Universities of Nottingham, Bristol, Cranfield and Manchester.

The Bristol project, led by Professor Kevin Potter is exploring ‘Novel approaches to the manufacture of complex geometries from broad-goods’ and through a platform position investigates ‘Composite design and manufacturing for integrated product development’.

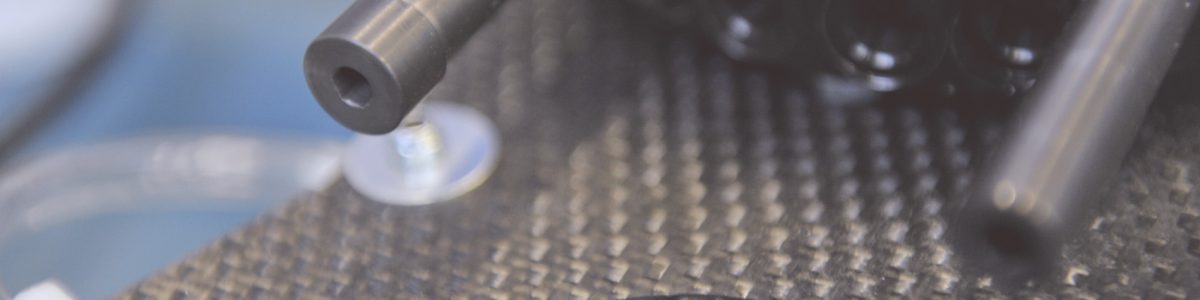

The principal focus to date has been the development of an in-depth understanding of how selected reinforcements can be manipulated in/onto tool geometries rapidly and without defects. It has been achieved by Michael Elkington studying how operators manipulate a reinforcement onto the tool surface through investigating the sorts of grips, tools, and techniques used by experienced and novice operators in laying up prepreg onto a series of increasingly difficult geometries. A catalogue of common techniques and their specific uses has been developed and reported on from this work. This knowledge could be used to train operators, and/or to better-inform on the best-available routes to form those complex features, and also to better inform the future design of automated sheet prepreg layup systems.

In parallel to this, the relationship between the properties of reinforcement materials, tool geometry, and lay-up time has been investigated by Dominic Bloom using the same team of experienced operators and tool-set. Using unambiguous instructions a five-fold difference in lay-up times was seen across a range of typical geometries. Furthermore it was found that the choice of prepreg could influence layup times by up to a factor of two. By reviewing the properties of reinforcements for drape and their interaction, such as shear stiffness and tack quality, the reinforcement properties leading to rapid lay-up have been identified and reported. This potentially allows for the development of improved materials for meeting rate and quality in manufacturing.

These works now move forward into exciting new areas. Michael Elkington has identified an alternative approach to manual lay-up, involving offline pre-shearing of the ply in order to conduct the major cloth reorganisation via a fast and reliable route. The approach minimises the amount of tool/reinforcement interactions needed, speeding-up lay-up without impacting on part quality. Dominic Bloom is investigating the shear energy in forming, using it to explore a definition of work to form a feature or geometry as a manufacturing index. Such a definition will allow for the development of immediately more-manufacturable parts in the design environment. These works will be used to inform on alternate processes for manufacture of composite parts with short-term goals of minimising manual lay-up times and long-term targets to automate the lay-up process. All works are also done in lieu of works at the National Composites Centre so that outputs complement each other’s activities, maximising impact and possible follow on research.

The work by Dr. Anna Chatzimichali investigates the development of manufacturing capabilities in the production of composite components through demystifying the ‘black art’ of producing and industrialising composite components. It is focused on the industrial landscape and the current challenges that the composite sector is facing, particularly the interface between design and manufacturing in the development of composite components across the supply chain. Through in-depth interviews, a number of experts with an average of 30.5 years of experience have shared their knowledge in the practice of developing composite products. This qualitative dataset is now being utilised to develop a theoretical underpinning of the strategies that can accelerate composite sector growth, to enable the UK market to meet global demand now and in the future.

The other three projects in progress under CIMComp are as follows.

- Multi-Scale Modelling to Predict Defect Formation during Resin Infusion (Lead organisation: University of Nottingham);

- Structural Joints using Novel Embedded Inserts (led by Cranfield University); and

- Innovative Multi-Material and Multi-Architecture Preforms (Lead organisation: University of Manchester).

For more information on CIMComp, please visit the organisation’s website.