EPSRC Future Composites Manufacturing Research Hub Host Researcher Network Online Event May 2023

Published: 12th May 2023

The Researcher Network organised an online event for Hub Students and Researchers on 3rd May 2023.

The event programme consisted of 5-minute presentations from 7 members of the Researcher Network, all from different Hub spoke institution’s, it was a good opportunity for the audience to be informed about their current research and make connections and collaborations within the Hub.

The presentations were judged by the attending audience and the following people were awarded prizes.

1st placed presentation: Paloma Rodriguez Santana, University of Bath, ‘A Quick Overview of Structural Batteries’. Structural batteries are devices that combine the load-bearing and electrochemical storage capabilities of carbon fibres (CFs), thus enabling reversible electrochemical energy storage whilst simultaneously under mechanical loading conditions. This offers significant opportunities for weight saving in aerospace and automotive applications. Recent research has shown the potential of polyacrylonitrile (PAN) based fibres for structural battery anode applications, with LiFePO4 coated fibres showing potential as cathodes. By embedding these fibres in a biphasic structural electrolyte, the resulting carbon fibre-polymer composite structure has the high specific strength/stiffness required for lightweight structural applications and the high ionic conductivity required for battery functionality.

2nd placed presentation: Patrick Sullivan, University of Bristol, ‘Recycling Carbon Fibre’. A quick snapshot of 3 years of research undertaken to explore the issues of commercial scale recycling of carbon fibre reinforced polymers and materials that use reclaimed carbon fibres.

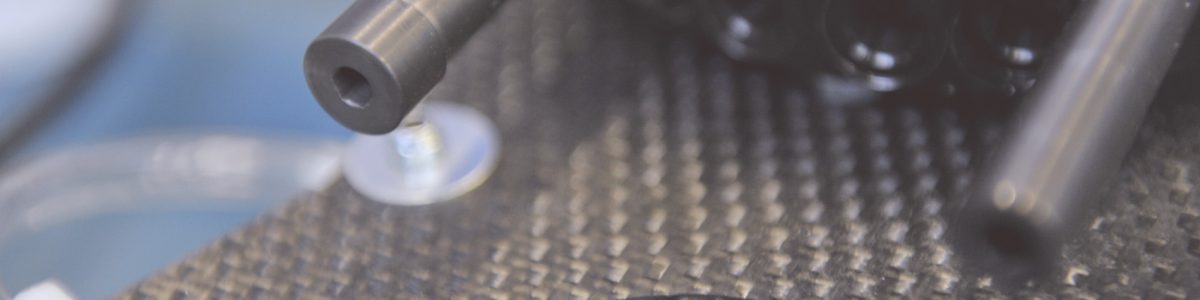

3rd placed presentation: Monali Dahale, The National Composites Centre, ‘Influence of weave parameters on the mechanical and crash performance of 3D woven composite’. The application of 3D woven composites in advanced structural components is limited by a lack of understanding of the influence of textile weaving parameters on the final architecture, mechanical and impact performance. This work investigated effect of fundamental and easily adjustable weave parameter (weft density) on the mechanical and crash performance in 3D woven warp interlock layer-to-layer carbon/epoxy composite structures. The purpose of this work was to enhance the performance of 3D woven composites by reducing the manufacturing time, cost, and complexity. 3D fabric preforms were manufactured in two different weft densities: 4 and 10 wefts/cm and a constant warp density of 12 warps/cm. Increasing the weft density improved mechanical and crash performance along both the longitudinal and transverse directions. This work shows that minor weft direction (transverse) weave changes can lead to sizeable improvements in warp direction (axial) energy absorption and mechanical performance without fundamentally redesigning the weave architecture.

The event closed with a social quiz which was enjoyed by all who attended. The next Researcher Network event will take place in Belfast during the ICCM23 conference. https://iccm23.org/about-the-conference/

To find out more information or to join the Researchers Network please click here