Zero-waste manufacturing of highly optimised composites with hybrid architectures

Host Institutions: The University of Nottingham, University of Warwick

Start Date: 1st November, 2022

Duration: 12 months

Lead Investigator: Connie Qian

Co-Investigator: Lee Harper

Aims

Composites manufacturing using prepreg typically generates 30%-50% of waste, which usually ends up in landfill, having negative impact on the environment and resulting in substantial costs. This research aims to create a practical solution for prepreg waste by co-moulding continuous fibre prepreg with discontinuous formats of waste prepreg to form a hybrid material. The new process will combine discrete continuous fibre prepreg patches and prepreg chip based SMC from recycled prepreg manufacturing waste, along with the virgin continuous prepreg to achieve 100% material utilisation.

Key objectives include:

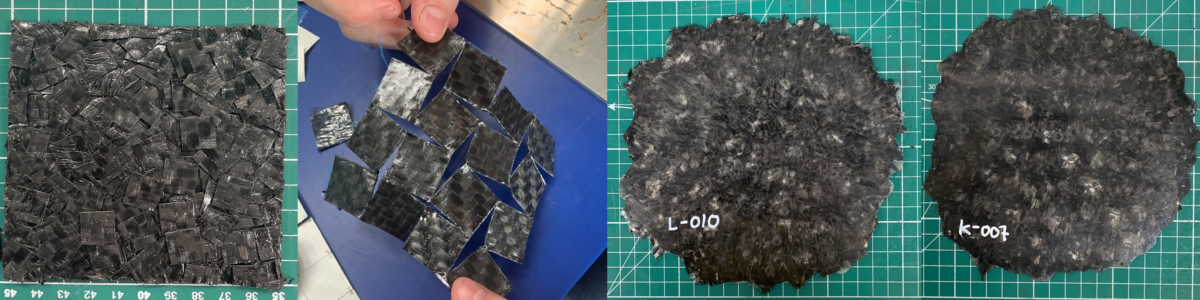

- Develop a robust re-processing method for manufacturing prepreg-based SMC.

- Determine the optimum chip size for the prepreg-based SMC through experimental flow characterisation to maximise the material’s ability to flow both in-plane and out-of-plane.

- Explore a range of nesting strategies for prepreg patches through experimental compression moulding trials.

- Manufacture of demonstrator components using the proposed new hybrid moulding process to achieve zero-waste target.