Work stream 5: Resin injection into reinforcement with uncertain heterogeneous properties: NDE and control

Host Institution: The University of Nottingham

Start Date: 1st November, 2019

Duration: 36 months

Lead Investigator: Michael Tretyakov

Co-Investigators: Andreas Endruweit, Andrew Long, Andrew Parsons, Marco Iglesias, Mikhail Matveev

Aims

The key requirements of the composite industry are to have repeatable mechanical properties of composite components, to minimise possibility of defects, and to have repeatable production cycles. For the RTM process to be used for high-value components, appearance of dry spots (i.e., defects) should be prevented. Appearance of voids and deviations from the designed filling time are caused by uncertainties in the material and process parameters, which cannot be realistically fully eliminated. To counteract the effect of the deviations, manufacturers use more conservative designs with larger safety factors. These conservative designs increase the total manufacturing and life-cycle costs. Furthermore, defects occurring because of uncertainties can lead to costly rework or higher scrap rate, which again increase the costs. The ability to quantify and control these uncertainties is of great importance for further advances in composites manufacturing. Currently, NDE and rework can take 10% to 30% of the overall manufacturing time in the aerospace industry. Finding new solutions for reducing this time is of the highest significance.

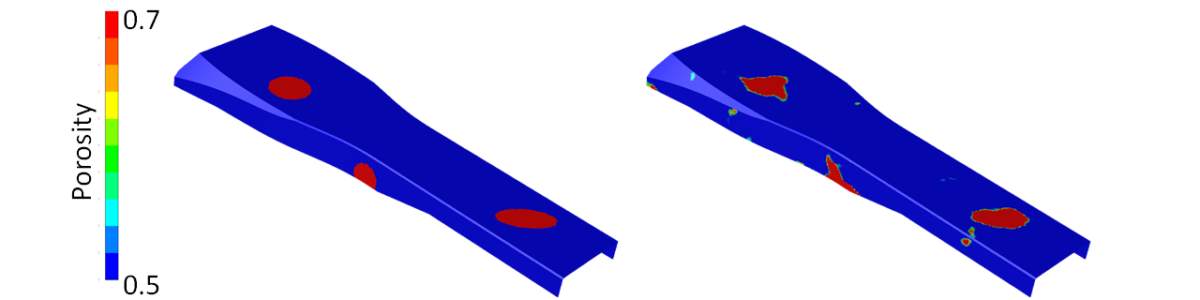

Our vision is to use in-process information from sensors during resin injection for reliable and quick NDE of composite parts and for an active control system to counteract random deviations from the design. Utilisation of in-process data will capture and estimate local deviations from the design for any manufactured part which will create a digital twin for this part. This significant advancement will deliver a major step-change in composites manufacturing by reducing the cost and increasing the robustness of the manufacturing process, thus improving confidence in the parts quality. The project will develop, improve and test innovative Bayesian inversion algorithms to restore permeability of composites components based on data collected from sensors during resin injection into reinforcement. It will also develop and test an active control system based on information from sensors and on physical models together with on-line parameter estimation algorithms to improve resin injection. This control system will minimise occurrence of defects and ensure the process robustness.

Evidence of Impact

Guest speaker: Francisco Chinesta, Professor of Computational physics at ENSAM Institute of Technology (Paris), presented his work on data-driven modelling ‘Empowering Hybrid Twins from Physics-Informed Artificial Intelligence’.