Dipa Roy

Dr Dipa Roy

University of Edinburgh

Spoke Representative

Dr Dipa Roy is Spoke Representative for the Hub and Lecturer in Composite Materials Processing at the University of Edinburgh. Her research focus is in Materials and Structures, in the Institute for Materials and Processes, Mechanical Engineering, within the School of Engineering. Dr Roy leads the Feasibility Study, 'Manufacturing Thermoplastic Fibre Metal Laminates by the In-Situ Polymerisation Route'.

Here, Dipa introduces herself and her Feasibility Study:

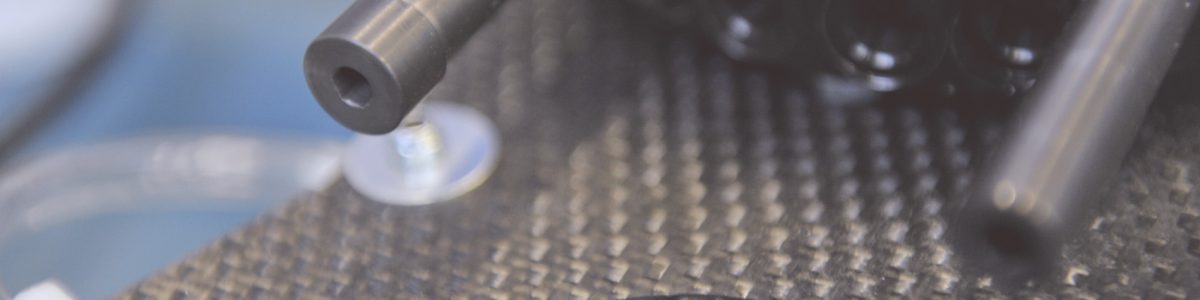

"Fibre Metal hybrid Laminates (FMLs), where thin metal sheets and fibre-reinforced composites are integrated, offer the superior characteristics of the composites combined with the ductility of the metals. Hybrid composites containing continuous fibre-reinforced plies and metal layers offer unique mechanical properties. The damage threshold energy of such hybrid laminates is significantly higher than the values offered by traditional engineering materials. Typical examples of such composites include GLARE (glass fibre/aluminium), ARALL (aramid fibre/aluminium) and CALL (carbon fibre/aluminium), which are mostly manufactured by prepreg/autoclave technology. Such thermoset FMLs exhibit superior properties, but possess some distinct drawbacks such as poor interlaminar shear strength, non-reparability and non-recyclability. In recent times, thermoplastic FMLs are being investigated by researchers, which can offer advantages over thermoset FMLs such as higher interlaminar fracture toughness coupled with weldability and recyclability. It is envisioned that these thermoplastic FMLs will be of interest to industries such as automotive, renewable energy, construction etc. In this feasibility project, thermoplastic FMLs will be manufactured by a resin infusion route using an in situ polymerisation process as the key step to bond surface-treated metal with the polymer, without the use of any adhesive layer. This approach of manufacturing a thermoplastic FML is quite novel. As the bonding layer will be thermoplastic, it will be reversible in nature and will be suitable for recycling and re-use.

The University of Edinburgh is delighted to be introduced as a new spoke institution in The EPSRC Future Composites Manufacturing Hub. We will work in conjunction with other spoke members of the Hub to deliver a step change in the properties, processability, production and recyclability of polymer matrix composites. I have moved to the UK from Ireland only in January 2017 and am honoured and delighted to have been awarded this EPSRC feasibility project. We are anticipating that our work will produce high quality literature publications, generate IP and give UK industry a competitive edge in the utilisation of composites across a number of sectors. A successful outcome to this feasibility study will give us the confidence and credibility to apply for further funding from EPSRC and, indeed, facilitate our participation in international proposals through Horizon 2020 as well as in the new EPSRC-Science Foundation Ireland funding initiative.

Before moving to the UK, I worked with the Irish Composites Centre (IComp), University of Limerick, Ireland, for more than five years where I participated in many industry-led R&D projects. Joining the composites group at the University of Edinburgh has been a great privilege for me. Since its inception in 2015, the Composites Group here has marked its presence with many successful research proposals. With this feasibility project and, hopefully, a follow-on project, we anticipate developing, with the support of industrial members, low-cost, high performance, readily processable and recyclable hybrid metal-composite laminates, which will find wide-spread application in, for example, the automotive, renewable energy and construction sectors."