Home > International Partners > The University of British Columbia

The University of British Columbia

International Partner Lead Academic: Professor Anoush Poursartip

The Composites Research Network (CRN) at the University of British Columbia is a collaboration of academia and industry partners supporting the composites industry in Western Canada and beyond. It was launched in January 2012 with a $9.8m investment from Western Economic Diversification Canada. Vision: A vibrant leading-edge composites industry, supported by the CRN and partner organizations. Mission: To create knowledge in practice documents that enable effective and low-risk knowledge-based composites manufacturing and design. Location: The CRN has its hub at The University of British Columbia (UBC) in Vancouver and other nodes located across Canada.

The Composites Research Network works with small- and medium-sized companies (SMEs) to support the continued growth and maturation of the composites manufacturing capacity. This work takes the form of short term projects which address the business needs of the client organization while also connecting to the underlying fundamental science which supports composites manufacturing.

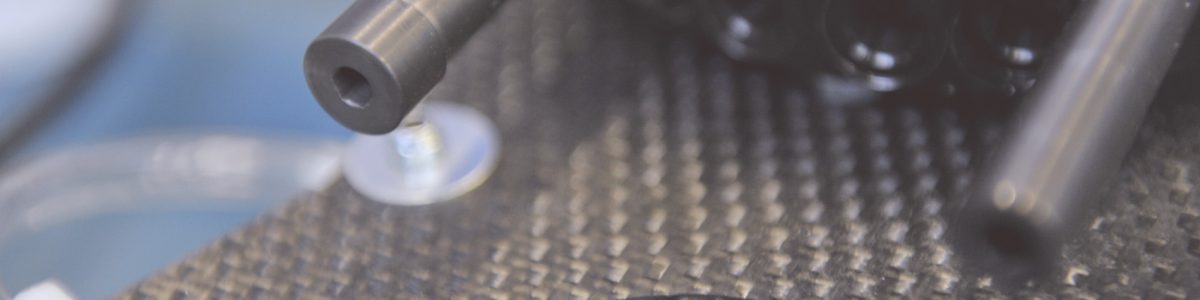

Building on the success of introducing simulation to composites manufacturing to reduce risk, cost, and schedule, CRN is developing, in conjunction with its industrial members, an exciting new initiative to reimagine composites manufacturing for the 21st century, bringing together simulation, sensors and data analytics, and automation: the Learning Factory.

The physical factory will have a core capability which is the current, qualified production baseline. The factory will be immensely data rich, with multiple layers of sensors and data analysis. It will be sized to allow for both standard production and research production. It will be highly reconfigurable and multi-layered in its ability to allow different sensor and data analysis technologies to be implemented and researched. There will be a digital twin in the cloud, where a virtual factory based on simulation will be used, in combination with the rich data from the physical factory, to understand, manage, and improve advanced composites manufacturing processes.

The factory will be physically designed to be a mixed use facility, satisfying both academic and industrial requirements. It will be part of the UBC Okanagan campus, a key tenant of the new Innovation Precinct, and will be conducive for interaction and collaboration. Equal attention is being paid to the virtual factory, which will be hosted at the UBC Vancouver campus, where the combination of big sensor and data capacity from the physical factory will be combined with simulation to understand, control, and optimize the production of advanced aerospace composites structures.

For further information on research, equipment, and learning, visit their website.