Home > International Partners > KU Leuven

KU Leuven

Hub International Partner Lead Academic: Professor Stepan Lomov

Within the Faculty Of Engineering Science, the Department of Materials Engineering (MTM) of KU Leuven is engaged in ‘Materials’ research (to develop and study new materials and processes to shape these materials), education (providing a solid metallurgical and materials background to future materials engineers), and services (offering third parties expertise and advice concerning failure analysis, non-destructive testing, surface technology, polymer matrix composites, powder metallurgy, and pyro-metallurgical processes, among other areas).

The research activities are organized into three research units: SCALINT (Structural Composites and Alloys, Integrity and Non-destructive Testing), SIEM (Surface and Interface Engineered Materials), and SeMPeR (Sustainable Metals Processing and Recycling).

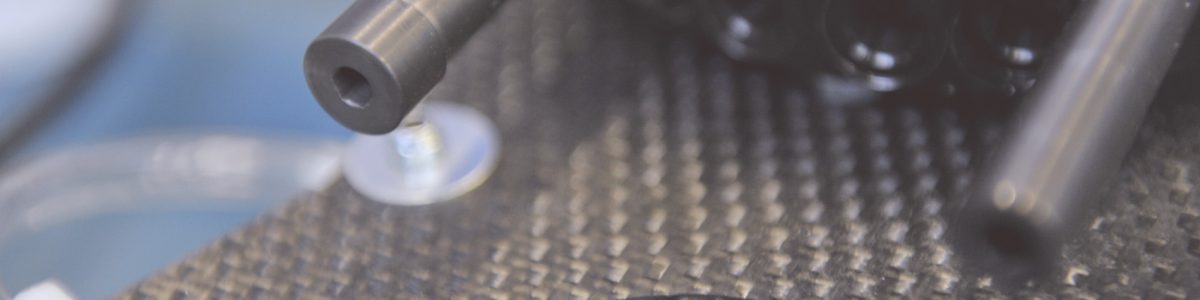

The Composite Materials Group (CMG) conducts research on polymer matrix composites. The CMG is a worldwide recognised centre for composite materials research, and the host of the Toray Chair for Composite Materials, with Prof S.V. Lomov holding the Toray professorship and Prof I. Verpoest as Emeritus Toray Professor. Research in focused around five main research themes: Composites on micro/nano scale (coordinated by dr. L. Gorbatikh); Processing and application development (coordinated by Prof. J. Ivens and Prof. F. Desplentere); Composites on meso/macro scale (coordinated by Prof. S. V. Lomov); Physical chemistry of composites (coordinated by Prof. D. Seveno); and Natural fibre composites (coordinated by Prof. A. van Vuure).

Specific research on manufacturing and application development of composites, for which a large amount of manufacturing equipment has been acquired or developed at MTM, aims to enhance the applicability of composite materials by the concurrent development and optimization of composite materials, products and their manufacturing processes. Ongoing manufacturing and application development research projects include: Development of advanced thermoplastic UD tapes for high pressure gas vessels; KIC LightRight: Materials for lightweight design – how to treat them right; VIS CompositeBoost: substantiated selection and robust composite manufacturing; Advancement of Measurement Technques and Simulations for Permeability of Textile Preforms for Composites (PERMEA) ; Industrial predictive CAE solutions and validation for nominal and as-manufactured strength of composite material systems: balancing light-weight and performance; Optimization of the heating process during thermoforming; Development of fully biobased injection moulded products; Development of low-cost flax preforms for high-performance composites; Development of new cycling helmet standard tests for improved head impact protection; Conceptual completion and development of a prototype of an optimized bicycle helmet for improved head protection of young and adult cyclists; Development and evaluation of anisotropic foams for improved rotational impact resistance of bicycle helmets.

The new materials and material production and material transformation processes that we develop in the department contribute to the technologies and applications of tomorrow. Examples include work on new and improved recycling concepts and processes, biodegradable composites, new alloys to replace lead-containing components, materials for lithium batteries, sensors based on functional materials, bone scaffolds, ceramic gradient materials, ultra-strong steels.

The research activities of the Department MTM are funded by the University, the Flemish, Belgian and European governments, as well as numerous industrial partners. To achieve all this, MTM has a staff of nearly 200 employees. The deployment of these co-workers makes numerous technical achievements and important research results on an international level possible. An important mission of our professors is the guidance of doctoral students and the care of the doctoral education program. These activities are closely linked with the research in MTM.

You can download their research group’s presentation, or visit their website here: