Home > International Partners > Swiss Federal Institute of Technology, Lausanne (EPFL)

Swiss Federal Institute of Technology, Lausanne (EPFL)

Hub International Partner Lead Academic: Professor Véronique Michaud

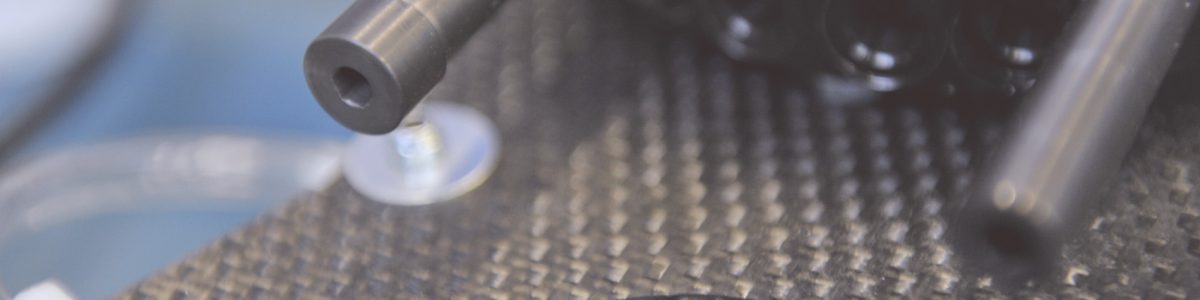

The objective of the Laboratory for Processing of Advanced Composites (LPAC) at EPFL is to establish the scientific base for the next generation of materials and processes in the fast-growing fields of polymers and composites. This involves novel approaches to tailoring material systems and process cycles, development of new materials with controlled rheology, solidification kinetics and surface characteristics, process simulation and costing, and quantitative durability analysis for optimal life cycle strategies.

LPAC develops advanced processes for thermoset and thermoplastic composites, based on a fundamental understanding of flow and interfacial mechanisms. Focus is also put on smart composites, bioinspired composites, UV-curable composites, nanostructured materials, multilayer films, functional surfaces and life cycle engineering.

LPAC is a new lab at the Institute of Materials and benefits from former LTC’s (Polymer and Composite Technology Lab) knowledge in developing new routes to cost-effective materials and manufacturing, incorporating unique additional functionality that goes well beyond classical performance criteria. Emphasis is placed on scaling up to an industrial context, particularly in the fields of aerospace, automotive, building, medical, electronics and sports.

The main competencies of LPAC are: Processing of multifunctional composites; Smart composites; Bioinspired composites; Nanocomposites & hybrids; Multilayers films; Functional surfaces; and Life cycle engineering. Facilities include: Chemistry lab (formulations of resins, hybrids, hydrogels and nanocomposites); Rheology lab (oscillatory shear (photo) rheometer, capillary rheometer, dynamic mechanical analyzer); Processing lab for thermal processes (wet layup, RTM, compression molding, autoclave); Processing lab for foaming and 3D printing (CO2 autoclaves, 3D printing units); Processing lab for UV processes (Hg sources, nanoimprint lithography, photo-interferometer, roll-to-roll UV printing); Analytical and testing labs (optical microscopes with in situ heating and electro-mechanical testing units, nanoparticle size analyzer, (photo) DSC, O2 and H2O permeation cells, mechanical and impact tests).

For more information about their research and teaching, visit their website.