University of Nottingham Advances in Multi-Scale Modelling EPSRC CIMComp Project

CIMComp Archive Press Release

Published: 4th June 2013

TexGen has now reached more than 15,000 downloads since its launch in 2006. The latest version, 3.5.3, which was released in November 2012, has been downloaded more than 1500 times.

TexGen is open-source software licensed under the General Public License developed at the University of Nottingham for modelling the geometry of textile structures. TexGen has been widely used as the basis of models for a variety of properties, including textile mechanics, permeability and composite mechanical behaviour. TexGen is an integral part of the multi-scale modelling project based at the University of Nottingham.

The project “Multi-Scale Modelling to Predict Defect Formation during Resin Infusion” is just one of four main research topics within the Engineering and Physical Sciences Research Council (EPSRC) Centre for Innovative Manufacturing in Composites (CIMComp).

CIMComp, led by the University of Nottingham, aims to deliver a co-ordinated programme of research activities at some of the leading universities in composites manufacturing, namely the universities of Nottingham, Bristol, Cranfield and Manchester.

The multi-scale modelling project, which is led by the University of Nottingham’s Polymer Composites Research group, aims to develop and validate an approach to predict variability and defect formation during liquid composite moulding, capturing the combined effects of material, geometry and process variables. This will incorporate variations in material properties and processing behaviour at the macro-, meso- and micro-scales.

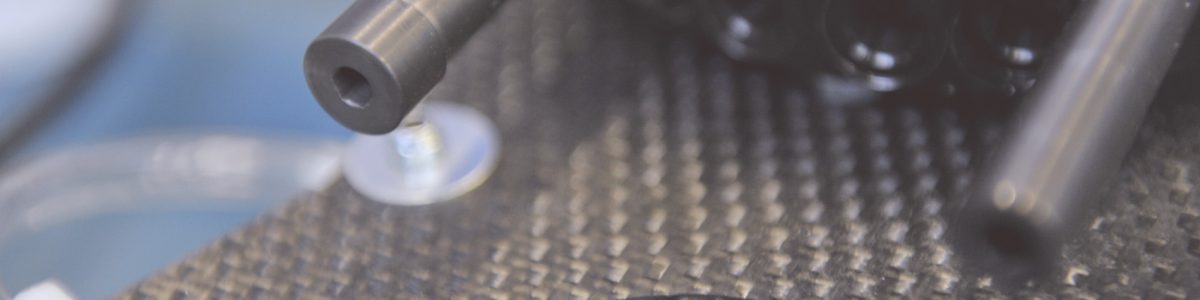

To address the issue, Nottingham is focused on modelling the inherent variability of reinforcements and its effect on impregnation with resin, particularly the formation of dry spots which negatively affect the performance of the finished component.

Since fibrous reinforcements are typically yarns, which are arranged in a repetitive pattern produced by weaving, braiding or other textile processes, a multi-scale approach has been implemented.

Non-uniform filament distributions within yarns in reinforcement fabrics are characterised experimentally, and a method for stochastic description of these distributions is developed. Based on detailed representative models of filament distributions, numerical simulation of resin flow through yarns indicated that the impregnation behaviour differs significantly from the idealised case implying that realistic degrees of non-uniformity cannot be neglected.

At the component-scale, the random misalignment of yarns in fabrics is characterised and its influence on flow patterns during impregnation simulated. This allows the range of probable outcomes of resin injections for textiles with realistic degrees of non-uniformity to be predicted and locations with increased probability for dry-spot formation to be identified.

In addition, the effect of the reinforcement history, in particular effects of reinforcement deformation due to gravity and handling is assessed experimentally. A strong influence of the reinforcement history on the textile structure and the impregnation behaviour was found.

The next stage of the project is to bridge the gap between modelling yarn-scale and component-scale effects by addressing resin-flow phenomena at the transitions between yarns and inter-yarn gaps in the reinforcements, which can result in void formation within yarns or between yarns.

The other three projects in progress under CIMComp are:

- Structural Joints using Novel Embedded Inserts (led by Cranfield University);

- Novel Approaches to the Manufacture of Complex Geometries from Broad Goods (led by the University of Bristol); and

- Innovative Multi-Material and Multi-Architecture Preforms (led by the University of Manchester).

For more information on CIMComp, please visit the organisation’s website.