The EPSRC Future Composites Manufacturing Research Hub Announces Optimisation of Fabric Architectures Webinar

Published: 17th May 2021

The EPSRC Future Composites Manufacturing Research Hub (Hub) is pleased to announce a free to attend webinar, focused on ‘New Manufacturing Techniques for Optimised Fibre Architectures’, taking place at 11:00 GMT on Wednesday 26th May.

The Hub engages academics and industry from across the UK to deliver a step-change in the production of polymer matrix composites.

This webinar will look at the latest research and development projects working towards that change.

Optimisation of Fabric Architectures

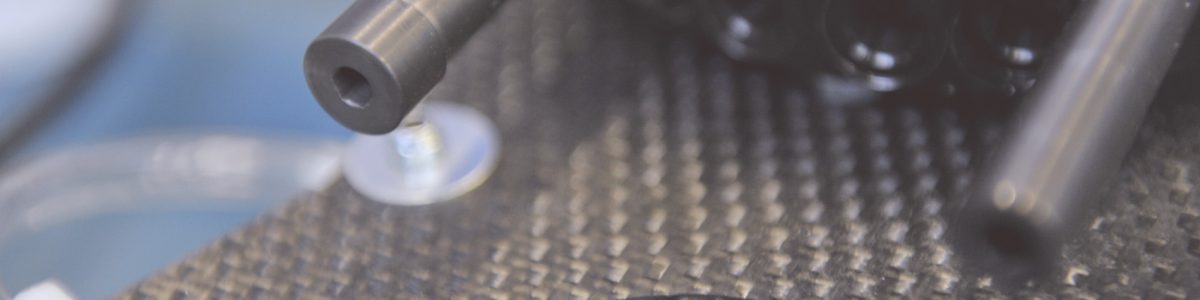

“New Manufacturing Techniques for Optimised Fibre Architectures” is a collaboration between the University of Nottingham and the University of Manchester to develop new simulation and manufacturing capability in the UK for 3D woven materials.

The project aims to discover new forms of 3D fibre reinforcements to complement and extend currently available 3D textiles, such as orthogonal weaves or layer-to-layer weaves. Areas of focus will include braiding and cylindrical preforming. This aim is being achieved by establishing a computational framework for textile preform optimisation not limited to existing manufacturing technologies.

The framework is being built and extended, based on a series of case studies to identify classes of materials with improved properties. New manufacturing technologies are being developed for these materials and used to validate the predicted properties. A computational framework, based on a “virtual testing” approach, is evaluating properties of various composites designs and together with an optimisation algorithm selecting the best solution. Optimisation algorithms used within the framework enable prediction of the best possible solution or a range of optimal solutions (a Pareto front).

A series of case studies, nominated by industrial partners, provide a test ground for the project and will demonstrate the weight-savings or improvement in performance achieved by optimisation of fibre preforms. New manufacturing techniques will be developed to create the optimised fibre preforms, either by the modification of existing textile processes, or by developing entirely new manufacturing processes. The manufactured samples will be used for the validation of the optimisation approach.

Agenda

- Introduction of the Optimise Workstream (5 min, Prof. Nick Warrior)

- New Manufacturing Techniques for Optimised Fibre Architectures (5 min, Prof. Andy Long)

- Development of New Manufacturing Techniques for Complex Preforms (10 min, Prof. Prasad Potluri)

- Numerical Framework for Optimisation of Fibre Preforms (15 min, Dr Louise Brown / Dr Mikhail Matveev)

- Optimisation of 3D Woven T-joints (5 min, George Spackman)

- Manufacturing of Optimised Preforms: Case Studies (10 min, Dr Vivek Koncherry / Dr Shankhachur Roy)

Attendees will be given the opportunity to ask questions during a Q&A session at the end of the webinar.

Places are limited and registration is via Livestorm – https://app.livestorm.co/fluency-marketing/cimcomp-optimisation-of-fabric-architectures

A recording of the webinar will be made available on the CIMComp website after the event.