Novel approaches to the manufacture of complex geometries from broad goods

Host Institution: The University of Bristol

Aims

Develop novel approaches to the manufacture of composite parts through an understanding of reinforcement manipulation, and the development of appropriate low-cost automation methods. The short term target of all of these elements of the programme is to minimise manual lay-up times, the long term target is to automate the lay-up process.

Progress

Following on from the CIMComp Feasibility Study project ‘Intelligent composite lay-up by the application of discrete technologies’ (RGS 109192), we have commenced a new body of work to explore the use of Virtual Reality and Augmented Reality in composites assembly and repair. The initial target for the work is to identify gaming & gamification processes for manufacturing and MRO style activities, with expectation of delivering a knowledge repository for decision making in technology adoption for particular tasks.

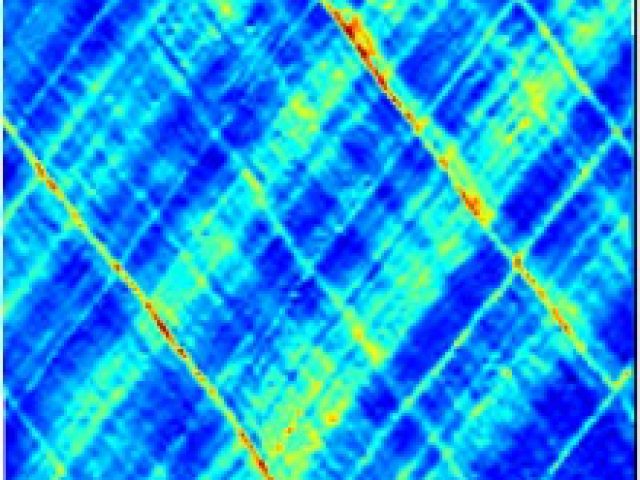

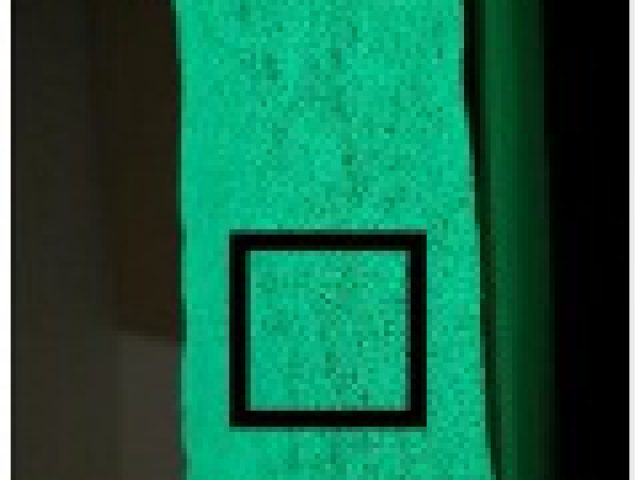

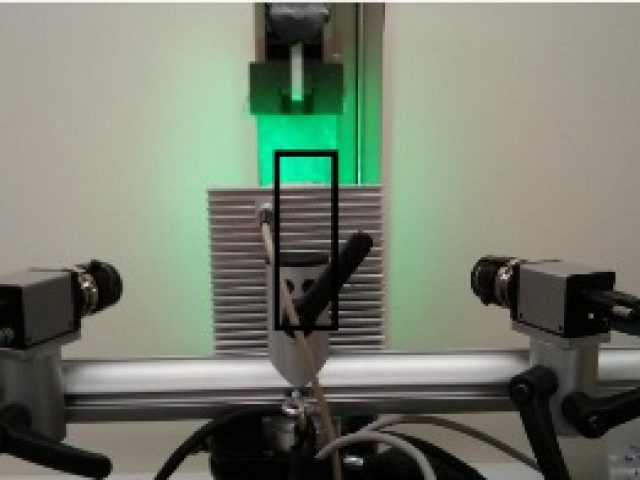

Complex materials: has recently concentrated on developing a more detailed analysis of the materials in mechanical performance using DIC. This work has been very fruitful, developing 3D materials image analysis that is unsurpassed in known literature. The test process is still being undertaken in rates similar to that in layup, and some additional materials have been tested, to expand the portfolio of products considered. The research into complex geometries has recently begun to expand into the manufacturing use of aligned short fibre materials. A highlight of the progress to date includes the very in-depth analysis of literature, delivering a knowledge repository for technique development, and a timeline analysis. This has enabled a ‘needs in the materials’ process tree to be devised, and which the team will apply into a KPI study shortly. Recent activity has also included assessment of the evolution of air entrapment at the tool/ply interface during layup, in particular when using layup tools, and the impact of bagging variation in pleats etc. Bagging issues and complexity has been further demonstrated by use of a pressure sensitive film over complex surfaces to review best practice. In order to begin to correlate previous activities in layup difficulty, materials (complex and simple), and bagging issues; some initial works towards reviewing geometrical impacts as a manufacturing index of difficulty has been explored. The work aims to show how some features are more difficult than others by exploiting the data developed and in part demonstrate a route forward for a predictive capacity in design for manufacture.

Simple materials: The research has completed the analysis on the routes to preshearing and has reported on the application of the process over several geometries. The work has been very successful with productivity and repeatable quality gains evident by the approach. The development of the technique in a manual form led to a press-form type of mechanical solution to be developed. This press-forming approach has been built and under lab trials the technique shows viability. Work now concentrates on exploring the use of robotics to undertake the fine layup works in final deposition such as conforming to radii. End effectors to enable this have been built and tested, as well as simulation trials (in part in collaboration with LCC at TUM). Those trials have shown promise, and now lab based proof of concept experiments using the ABB robots platform is being undertaken. This will lead up to a demonstrator that will manufacture a complex geometry using only the stamp preform and robotic conforming techniques as developed. In parallel to this automation work, research has begun that aims to explore the delivery mechanisms for knowledge capture and exploitation (including the use of simple tools), and on experiments with materials to explore the capability to preform and apply materials without ‘design rules’ as such.

Robotic pick and place: new developments of incorporating 3D printing directly to the manufacturing process have recently been made. The new approach has been undertaken in a mechanical test frame to simulate simple robotic motion, but shows remarkable results to date. The team has been able to show the pick and place of a lower skin, manufacture of a complex geometry core material in-situ to the lower skin, and the continued pick and place of the top skin thereafter. It is thought such a demonstration is a world’s first as no manual interaction in deposition of any kind occurs. The process is progressing to a simple robotic arm (in research on associated works), to deliver the core and skins in a fully automated form (by changing end effectors). The potential ability to develop the core in-situ via 3D printing has opened up a significant area of design possibility, and research to explore this is now beginning. Other flexible end effector designs, and more rigid gripper trials, works continue. For example the previously designed film peeling end effector has been applied to a partner’s activity of automated bonding in metallic structures.

Finally, in the novel use of scrap as high value applications, research has concentrated on delivering scrap evaluation simulation models through LS-Dyna and Matlab, as well as a mechanical performance programme that will enable the team to identify the best use for the material going forward.

Key Achievements

- The first in-depth study of the factors controlling rate and quality of production in manual lay-up has been completed, offering opportunities to design part geometries and materials to deliver minimum labour costs.

- A low cost approach to supporting shop floor staff to deliver a well-controlled and high quality lay-up has been developed to a demonstration stage, including elements of software, hardware and manual aids.

- A significant improvement has been made in understanding quality critical aspects of composites processing using prepregs.

- The groundwork has been done to enable the development of effective robotic lay-up of prepregs on more complex tools, with demonstration parts imminent.

- Several items of the work are nearing TRL3, and exploitation through knowledge transfer via suitable outlets are in progress.