Home > International Partners > Fraunhofer ICT, Fraunhofer-Gesellschaft

Fraunhofer ICT, Fraunhofer-Gesellschaft

Hub International Partner Lead Academic: Professor Timo Huber

In the Polymer Engineering Department emphasis is placed on application-oriented research and the development of products to pilot production level. Our integration in the thematic networks of the Fraunhofer-Gesellschaft, our excellent contacts with other European countries and beyond, and our collaboration with the Karlsruhe Institute of Technology (KIT) means that we can offer our students and partners comprehensive research training and services that range from ideas via product, material and process development to the manufacture of prototypes.

Research areas in the Polymer Engineering Department include: Compounding and Extrusion (process and material development); Nanocomposites (the production of polymer compounds using nanoscale additives to adjust the electrical, mechanical or thermal properties of thermoplastic polymers); Foam Technologies (covering the entire development chain of foamed polymers from material development and the production of extrusion-foamed particles and semi-finished products through to the production of parts); Thermoplastic Processing; Thermoset Processing; High-performance Fiber Composites; Microwave and Plasma Technology; and Plastic Testing.

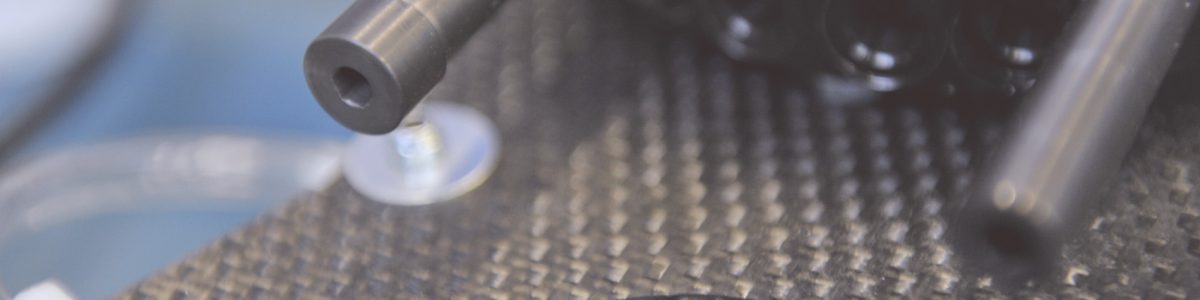

The research group for high-performance composites is concerned with material and processing tasks relating to resin transfer molding (RTM). The aim is the further development and industrialization of the process for the large-scale manufacturing of components made from high-performance composites based on thermosetting and thermoplastic (T-RTM) matrix resins. Research activities in the field of Textile technology, preforming and handling range from binder formulations and the modification of woven fabrics to improve their handling and draping properties, through to the development and evaluation of new preform processes. Activities in the field of thermoplastic RTM process (T-RTM) focus on material and process development for the manufacture of structural components using in-situ polymerizing thermoplastic matrix systems; in order to integrate the thermosetting RTM process into medium and large-scale production in the automotive sector, two new processing variants are currently being investigated and further developed, the so-called high-pressure compression RTM (HP-CRTM) and high-pressure injection RTM (HP-IRTM); the main focus of activities in the area of Continuous-RTM (pultrusion) is the resin-system optimization of Epoxy- and PUR-based systems, as well as the design optimization of closed resin injection & impregnation chambers.

International ventures include the Fraunhofer Project Center for Composites Research at the Ulsan National Institute of Science and Technology (FPC@UNIST), a comprehensive initiative between a Korean university and the Fraunhofer ICT, and the Fraunhofer Project Center @Western in London, Ontario, where the main research focus is the use of fiber composites in lightweight construction, especially in the automotive sector.

For more information about research, capabilities and facilities at Fraunhofer ICT-IMM, visit their website.