Home > International Partners > École Centrale de Nantes

École Centrale de Nantes

Hub International Partner Lead Academic: Professor Christophe Binetruy

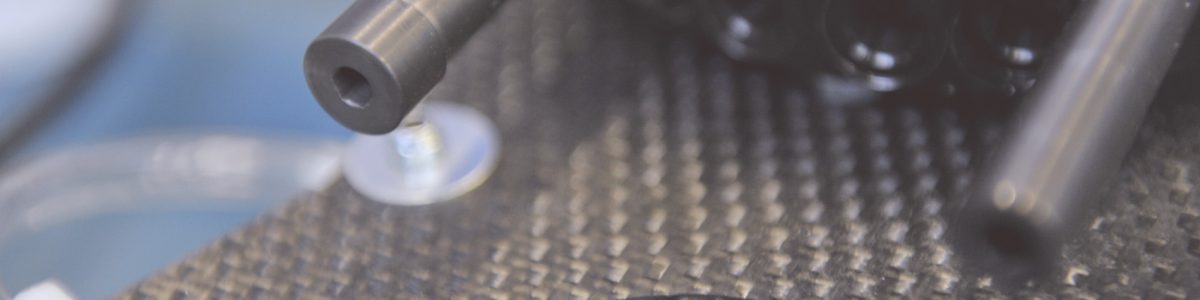

At École Centrale, numerous technological means of manufacturing composites are grouped together within the Composites Platform and Rapid Manufacturing Platform. The platforms provide the right conditions for world-class research activity conducted in the field of mechanics of materials and processes, and bring together manufacturing processes including additive manufacturing, machining, forming, welding, and bioprinting. International students selected by partner institutions abroad have the opportunity to spend one semester or one year of their studies at Centrale Nantes. They usually join the final year of the engineering programme choosing both a specialisation and a professional option, and courses are available in English and in French.

Research into Materials Science and Composites at École Centrale covers study of composites creation and design as well as the manufacture of industrial products. The study of the physical structure of the various materials (metals, polymers, ceramics, composites, biomaterials, etc.) and their properties leads to numerous industrial applications. The PMM Research Group (Processes and Mechanics of Materials) is headed by Professor Christophe Binetruy and comprises 25 PhDs and postdocs. Research fields and topics include design, modelling and technology of innovative processes (process constrained path generation, additive manufacturing, composite processes, high-pulse high-strain deformation processes, design for sustainable processes) and experimental techniques, modelling and numerical tools for the mechanics of materials (mechanics of elastomers, experimental and numerical integrated approaches). Other research Groups include Modelling and Simulation (MS), Materials-Environments-Structures (MEO), and Statistics, Probability, and Numerical Analysis (SPAN).

Beyond the scientific and technical motivation, the rational implementation of technological means on the premises provides for a thematic grouping of activities and an optimal management of incompatible experimental work (fine analysis equipment is separated from the machines used to produce the composites). This experimental equipment makes it possible to produce organic composites and to characterize materials in physical terms. Research work focuses on: process modelling (to reduce costs in non-autoclave processes, to allow for an optimized design for robotic placement and welding, and to produce at high speed via stamping of thermoplastic prepregs and semi-pregs, and high pressure RTM injection); calculation strategies (to facilitate the calculations used in the numerical simulation of processes using demonstrators based on model reduction techniques, particularly the PGD (Proper Generalized Decomposition) method); robust models of manufacturing processes (including digital and analytical tools capable of predicting the performance of manufacturing processes in order to simultaneously design the product and its process of industrialization under the more general concept of “Virtual Manufacturing”).

École Centrale currently has two industrial chairs:

– Faurecia, with Structural Composites for Automotive Application: numerical modelling and simulation of advanced composite manufacturing processes

– Joint Laboratory of Marine Technology with Naval Group: additive manufacturing for large parts and multi-physics numerical simulation, or the modelling and simulation of structures made with innovative materials

To find out more about their capabilities and equipment, visit their website.