PhD Student Designs and Develops Revolutionary New Tool – ‘The Dibber’

CIMComp Archive Press Release

Published: 6th January 2015

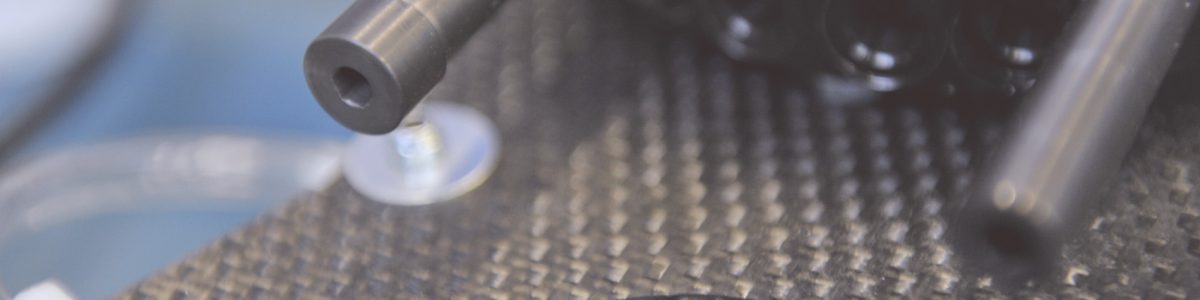

A PhD student from the University of Bristol, UK, has designed and developed a hand-held laminating tool, known as the dibber, for use in the layup of advanced composite components.

According to the University of Bristol, the manual tool could be used by laminators to manufacture composite materials in industries such as aerospace, car and transport. It explains, the ‘dibber’ was created by Helene Jones from the Department of Aerospace Engineering who has been exploring the existing design space in the manual layup of composite components as part of her PhD project.

Processing aids and tools play an important part in the layup of composite reinforcements to complex geometries. However, despite being frequently used by many industries the University says no in-depth study of these tools or how they are developed and applied has ever been carried out.

By working closely with experienced laminators, Helene identified the relationship between the workers and their tools. This led to the development of a series of prototypes, and then a final design and build using a colourless organic thermoplastic polymer, polyether ether ketone (PEEK), to create the dibber.

The University claims that the new tool, using three key attributes, comfort; geometry matching and force application as a design guide throughout, allows for a range of geometries and forming techniques. Early trial results with experienced commercial laminators have suggested that the dibber can be used to great effect, drastically reducing time in a particular layup without negatively impacting on finished quality. The dibber also potentially allows for a more standardised process in design and manufacture, especially if it is incorporated into training. This could lead to a reduction in costs and improve production rates.

Helene Jones said “Lamination is a highly skilled manual technique. It was important to understand why laminators create and use the tools they do. A standardised lamination process will be more successful if it is based on the needs of individual workers, the design, and the process of manufacture. This could lead to a more integrated design for manufacture and in skills training.”

Recently 200 dibbers were produced, using injection moulded acrylonitrile-butadiene-styrene (ABS), and examples distributed from the Centre for Innovative Manufacturing in Composites(CIMComp) stand at the Advanced Engineering Show held at the NEC in Birmingham held in November. The University says that feedback from companies and establishments who have been using the dibbers has been positive and the dibber has also had collaborative use in training demonstrations at the National Composites Centre (NCC).

Paul Shakspeare, Head of Training at the NCC said “The benefits of working with the dibber are that trainees can quickly adopt consistent methods during courses with the specifically designed tool. This early competence is then able to be translated into the workplace using the same tool and techniques.”

Helene is in the second year of her PhD in the Centre for Doctoral Training in Advanced Composites for Innovation and Science, working in collaboration with Dr Carwyn Ward, Professor Kevin Potter, Dr Ian Farrow and Dr Anna Chatzimichali.

Dr Ward, Lecturer in Composites Design, Processing and Manufacture in the Department of Aerospace Engineering, said “Helene’s work has opened up research areas and development paths for us to explore in design and manufacture, areas that we have been keen to investigate for some time. The use of knowledge such as this into design and manufacture allows us to develop the skill to link design and manufacture seamlessly together. This new understanding has been delivered in a deceptively simple form, but could have major industrial impact for the short and medium terms.”