Thermoplastic In Situ Polymerisation (TPIP) and Double Diaphragm Forming (DDF) for Moulding of Complex Parts at Scale

Host Institutions: The University of Nottingham, University of Edinburgh

Start Date: 1st September, 2022

Duration: 12 months

Lead Investigators: Andrew Parsons, Edward McCarthy

Co-Investigators: Conchur O’Bradaigh, Lee Harper

Aims

This project will establish thermoplastic composite manufacturing via in-situ polymerisation of polyamide in double diaphragm forming, demonstrating the capability using a realistic geometry tool and supporting the process with a forming model.

With increasingly pressing sustainability goals in all sectors, thermoplastic composite manufacturing developments are timely. Low cost, low emission processes are needed to create recyclable components that meet stringent regulations. The availability of very low viscosity (~10 cP) thermoplastic monomers combined with double diaphragm forming (DDF) presents a novel opportunity to create huge (multi-metre e.g. wind turbine, train body panels) thermoplastic structures using reaction injection moulding. DDF facilitates filling before forming; this is advantageous because the initially flat reinforcement is easier to infuse with resin than the fully formed part, thus achieving better and more even resin wetting of fabric, making this processing route compelling for industrialisation.

Aims and Objectives:

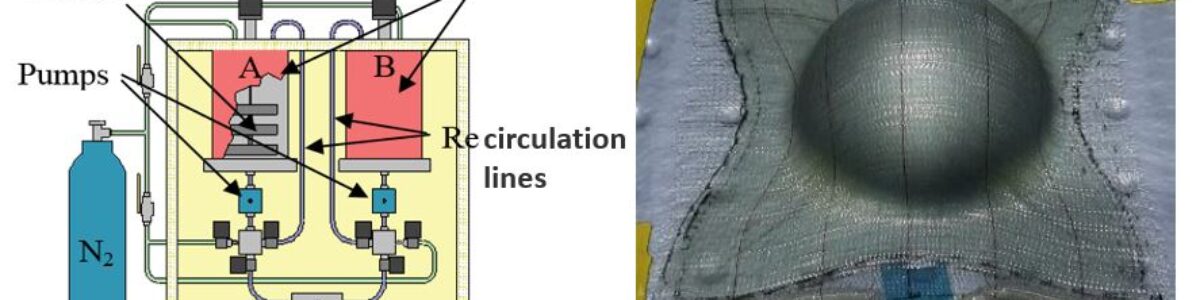

1) Assemble low-viscosity diaphragm forming system

In conjunction with AMRC (in an advisory role), develop the existing double diaphragm tooling at University of Nottingham to incorporate a bespoke frame suitable for a low viscosity resin system. Integrate with the University of Edinburgh mixing system. Specific clamp design elements will be required to ensure minimal bridging at the edge so as to prevent racetracking during fill.

2) Establish forming model

In conjunction with ESI, build on a basic model of the fill-form process using the PAM software suite to represent the tea tray geometry. Demonstrate virtually the benefits of the low viscosity (fast fill, lubrication) or waxy (high tack, resistance to corner thinning) resin on shear behaviour during forming in terms of fibre angle, wrinkling and corner thinning, and validate experimentally.

3) Establish processing method

Produce tea tray component in double diaphragm tool utilising one-stage fill and form, and two-stage quench and form. Ensure reproducibility and establish appropriate processing window.

4) Quality assessment and validation of model

Use metrology-grade 3D laser scanner (Creaform) and Apodius Vision System facilities to capture forming behaviour, distortion, fibre angle and wrinkles and correlate with model (Objective 2). Assess quality of the parts in terms of thermomechanical behaviour and microstructure.