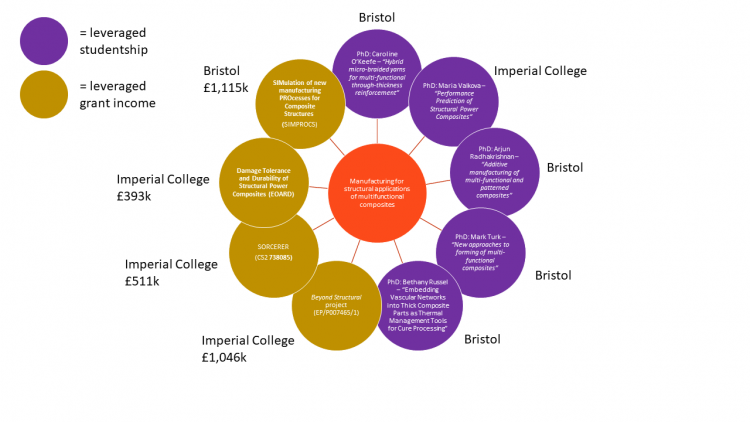

Work stream 3: Manufacturing for structural applications of multifunctional composites

Host Institutions: Imperial College London, The University of Bristol

Start Date: 1st September, 2017

Duration: 48 months

Lead Investigators: Dmitry Ivanov, Emile Greenhalgh

Co-Investigators: Arjun Radhakrishnan, Caroline O’Keeffe, Carwyn Ward, Chanhui Lee, Dmitry Ivanov, Emile Greenhalgh, Ian Gent, Ivana Partridge, Kaan Bilge, Maria Valkova, Mark Turk, Milo Shaffer, Sang Nguyen

Aims

This core project investigates the design and manufacturing issues associated with multifunctional composites, with particular focus on structural supercapacitors. These multifunctional materials simultaneously store (and deliver) electrical energy whilst carrying mechanical loads. Such multifunctional materials offer a completely different approach to using composites in transport and mobile electronics, and have the potential to provide a step change in weight and volume driven designs.

The research to date has focussed on demonstration of the concept and addressing the scientific challenges associated with this novel class of materials, but within this project, the general design and manufacturing issues associated with structural power materials are being addressed. Such research is vital to facilitate adoption of these materials by industry, and is of general relevance to a wide range of potential multifunctional composite systems, which must harmonise conflicting requirements.

The most promising approach for creating structural supercapacitors has been to embed structural carbon fibres in a monolithic carbon aerogel (CAG), which is a highly porous material consisting of a 3D network of interconnected nanosized particles. These materials have a typical surface area of 400–1100 m2/g and are used in conventional supercapacitors. CAGs are not suitable for structural applications alone, but they can be combined with structural carbon fibres to act as a scaffold to support them. Such CAG modified fibres demonstrate a 500 fold improvement in surface area (160 m2/g). Furthermore, the CAG offers huge improvements in critical mechanical properties, such as compression strength and delamination resistance (ILSS), as the CAG network extends into the polymer electrolyte/matrix, providing stiffening support.

The over-arching aim of the project is to investigate and address the design and manufacturing issues associated with multifunctional composites. This will specifically address the formability of CAG based multifunctional composites, the seamless integration of functional elements and multi-material domains in a composite system, and the heating and curing of composite precursors with added functions.

Aim 1: To explore the design and manufacturing issues associated with the fabrication of structural supercapacitors, which simultaneously store, and deliver, electrical energy whilst carrying mechanical loads. Such multifunctional materials offer a completely different approach to using composites in transport and mobile electronics, and have the potential to provide a step change in weight and volume driven designs.

Aim 2: To explore novel manufacturing methods for creating multi-matrix and multi-fibre graded composites and local integration of functionalised patches. The locality within the matrix is achieved through liquid resin printing, enabling integration of additive-rich resins in predefined patterns throughout the laminates. The specific focus of the matrix study is on the relation between processing parameters (injection, consolidation, curing), chemorheology of injected resins, and the morphology of printed patches. The specific focus of the fibre modification is the insertion of novel multi-material threads and fibres into dry fibre preforms, both in-plane and out-of-plane of the structure.

Progress

- One specific focus over the past year was to develop a viable method to enable structural power composites to be manufactured with complex geometries.

- Currently, the rigid CAG reinforcement used to enhance both mechanical and electrochemical performance hinders formabililty over a tool.

- Overcoming this challenge paves the way for structural power composites to be used in a much greater range of applications than would otherwise be possible

a) The project has been exploring new manufacturing approaches for creating a multi-material system combining various matrices, additives and sub-reinforcements in one integrated system. Efficient functionalisation of a structural composite can be achieved by a) incorporating matrices with added properties in continuously reinforced material, b) incorporating functional sub-reinforcements. Methods of combining composite matrices are not trivial and currently there exist no conventional industrial methods enabling manufacturing of multi-matrix composites with controlled boundaries between the domains. It has been shown that such composites can be created using innovative sequential infusion and imprinting domain boundaries. Efficient integration of functional reinforcement was realised using micro-braiding of yarns containing metal filaments and subsequently introducing them through tufting. Tailored matrix and reinforcement placement substantially expands the library of methods allowing to achieve high level of added properties, such as electrical and thermal conductivity, magnetic and induction susceptibility, etc. These properties enable sensing, new approaches to heating and curing, and repairability.

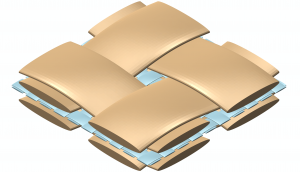

b) One of the fundamental challenges associated with structural supercapacitors is their formability. Carbon aerogel enabling energy storage is stiff and brittle and cannot be easily adapted to complex shape composites. Separating the domain of structural and functional materials paves the way to storing higher energy in complex shaped components. The newly tested approach showed the feasibility of creating islands of load bearing supercapacitors embedded into formable textiles. Subsequent infusion process allows to realise formable material containing multifunctional structural supercapacitors.

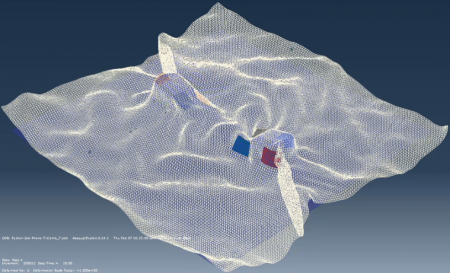

The project explored feasibility of new approaches to forming where precise introduction of imprinted elements, informed by numerical simulations, helps not only to place functional elements but also to mitigate against critical defects. It has been shown through simulations and manufacturing trials that placing stabilising elements in the critical location may help to redistribute fibre orientation and control deformation of the composite precursor. Patch placement allows simpler arrangements of the forming process and more sophisticated control of composite morphology. This approach is particularly relevant in the context of multi-domain composites where material costs are higher and hence, more attention needs to be paid to defect mitigation.

Key Achievements

- The process for manufacturing carbon aerogel-reinforced structural power devices has been scaled up, enabling batch production of laminates to be made with a higher carbon aerogel content than had previously been achieved.

- Trials involving direct printing of polylactic acid to mask selected regions of dry carbon fabric prior to the carbon aerogel manufacturing process have demonstrated that we can create internal domains (see Figure 1 and 2).

- Electrochemical deposition has been used to coat active elements onto the carbon aerogel to further enhance the electrochemical performance. Preliminary studies have been performed to optimise the deposition conditions to achieve the maximum electrochemical performance.

- Two suitable separator materials: spread glass fabric and a non-woven ceramic reinforced polyester, have been selected and acquired. Small scale multifunctional devices using these separators have been made and tested electrochemically, demonstrating energy and power performance (1.4 Wh/kg and 1.1 kW/ kg), exceeding the original aspirations.

- Conceptual designs have been developed for two structural supercapacitor aircraft door frames to demonstrate the capabilities to manufacture (a) curved components and (b) components having continuity of the load transfer between monofunctional and multifunctional zones.

- A finite element model of the multifunctional fabric-reinforced composites has been developed. The model realistically represents he internal architecture of the composite through consolidation process modelling (see Figure 3).

- Combined experimental and computational studies (see Figure 4) have demonstrated complex intra-yarn nesting of electrode and glass fabric plies to be a key microstructural feature of these composites, which arises during their consolidation. The increased nesting may enhance their delamination resistance as well as power density of these hybrid composites.

Evidence of Impact

Hub Director, Professor Nick Warrior, University of Nottingham introducing the ‘Hub Overview’.

Principle Investigator, Professor Emile Greenhalgh, Imperial College London introducing research completed on ‘Manufacturing For Structural Applications of Multifunctional Composites’.