Low-cost Manufacture of High-quality Steered-fibre Laminates

Host Institution: University of Glasgow

Lead Investigator: Philip Harrison

Aims

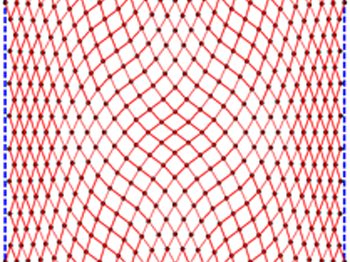

Steered fibre laminate technology typically involves manufacturing advanced composite laminates comprised of curved rather than straight fibre paths. The aim of fibre-steering is usually to optimise structural performance; holes and inserts in composite laminates can concentrate stresses, potentially becoming the focus of cracks and eventual failure. By steering fibres, stress concentrations can be reduced or eliminated. Another noted benefit of steered-fibre laminates is enhanced buckling resistance. This promising technology has already been adopted in manufacturing high-end aerospace structures and can significantly increase the design-space of advanced composite materials leading to highly optimised, lighter structures. Nevertheless, the technology has drawbacks, most notably its high cost. Typically, steered fibre laminates are manufactured using expensive Automated Fibre Placement (AFP) machines and despite high levels of automation, high capital costs and relatively slow laydown rates inevitably result in high costs per part. The AFP steering process can also results in defects; understanding and mitigating these defects is a research topic in its own right.

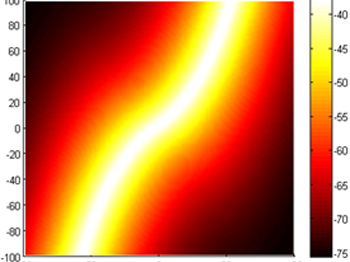

The current work offers an entirely different approach to manufacturing steered-fibre laminates. The benefits of the new method are much lower capital costs and defect-free manufacture of two-dimensional steered fibre laminates that, unlike most traditional AFP steered-fibre laminates, can be further processed into complex three-dimensional parts. To support the development of this new processing technology, novel computational design tools have been developed and integrated within the commercial finite element software, AbaqusTM. Inherent constraints in the manufacture process make the new approach less flexible in terms of generating arbitrary fibre orientations than AFP, though significantly lower manufacturing costs suggest a possible mid-ground production solution, bringing steered-fibre technology to mass market, lower cost applications.

Industrial exploitation of this concept is currently being discussed with an aerospace company and a proposal is being submitted to the EPSRC for major follow-on funding.

Contact: Dr Philip Harrison, School of Engineering, University of Glasgow

Website: https://www.gla.ac.uk/schools/engineering/staff/philipharrison/

Email: Philip.Harrison@glasgow.ac.uk